7016-high-low-temperature-lubricating-grease

7016 High & Low Temperature Lubricating Grease

Product Introduction

The 7016 High & Low Temperature Lubricating Grease is a high-performance specialty grease designed for bearings and mechanical components operating under extreme thermal conditions. It is formulated using synthetic base oil thickened with an organic thickener, combined with carefully selected antioxidants and functional additives. This advanced formulation ensures excellent lubrication reliability, long service life, and stable performance in both high-temperature and low-temperature environments.

Unlike general-purpose greases, 7016 is specifically developed to meet the demanding requirements of aviation electrical machinery and high-temperature industrial equipment, where conventional greases often fail due to oxidation, evaporation, or structural breakdown. Its balanced performance makes it a dependable solution for critical applications requiring consistent lubrication over a wide temperature range.

Formulation and Design Concept

7016 High & Low Temperature Lubricating Grease adopts a synthetic lubrication system that provides superior thermal stability compared with mineral oil-based products. The organic thickener structure offers strong resistance to mechanical shear, allowing the grease to maintain its consistency and lubricating film even under prolonged operation or vibration.

The inclusion of high-efficiency antioxidant additives significantly slows down oxidation reactions at elevated temperatures. As a result, the grease exhibits extremely low degradation and minimal evaporation loss, even during long-term exposure to heat. This design philosophy focuses on stability, durability, and safety, making 7016 suitable for continuous-duty and high-reliability applications.

Performance Characteristics

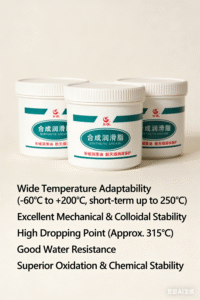

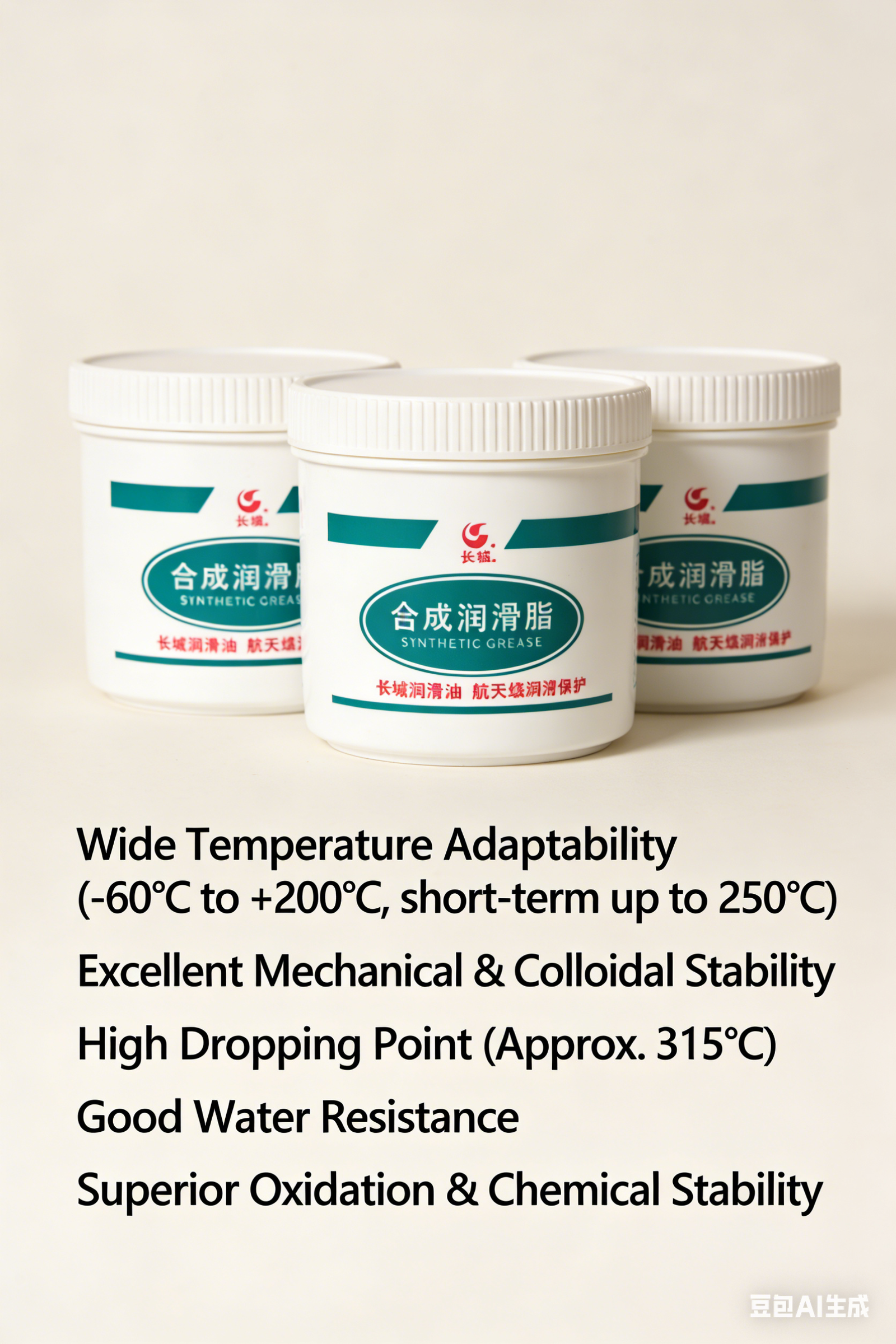

Wide Temperature Adaptability

7016 grease delivers reliable lubrication from –60 °C to +200 °C, with short-term temperature resistance up to 250 °C. At low temperatures, it maintains acceptable apparent viscosity, ensuring smooth bearing start-up and reduced friction. At high temperatures, it resists softening, oil separation, and oxidation, maintaining a stable lubricating film.

Excellent Mechanical and Colloidal Stability

The grease demonstrates strong resistance to mechanical stress, preventing breakdown of the thickener structure during high-speed rotation or long service cycles. Its excellent colloidal stability ensures uniform oil distribution within the grease matrix, allowing bearings to remain fully lubricated throughout operation.

High Dropping Point for Thermal Safety

With a dropping point of approximately 315 °C, 7016 grease provides a significant safety margin for high-temperature applications. This high dropping point minimizes the risk of grease leakage or loss under thermal stress, contributing to improved equipment reliability.

Good Water Resistance

7016 High & Low Temperature Lubricating Grease exhibits good resistance to water washout, allowing bearings to operate reliably in humid or moisture-prone environments. This property helps protect metal surfaces from corrosion and reduces lubrication failure caused by water contamination.

Outstanding Oxidation and Chemical Stability

Under severe oxidation testing conditions (0.78 MPa oxygen pressure at 100 °C for 500 hours), the grease shows zero pressure drop, indicating exceptional chemical stability. This performance ensures long service life and reduced maintenance frequency, even in high-temperature operating environments.

Typical Applications

7016 High & Low Temperature Lubricating Grease is especially suitable for aviation and industrial applications where bearings are exposed to high temperatures, temperature fluctuations, or continuous operation. Typical applications include:

-

Bearings in aviation electrical motors, such as generators, electric motors, and converters

-

Rolling bearings in high-temperature industrial machinery

-

Bearings operating under continuous or intermittent high thermal loads

-

Equipment requiring long lubrication intervals and high reliability

Its stable torque characteristics and thermal endurance make it well-suited for precision systems where lubrication failure could lead to significant performance loss or equipment damage.

Compliance and Quality Standard

This product is manufactured in accordance with Q/SH303 119 standard, ensuring consistent quality, performance reliability, and compliance with industrial requirements. Strict quality control is applied throughout the production process to guarantee product stability and repeatability.

Typical Technical Data

The following values represent typical characteristics and are not intended as specifications:

-

Appearance: Light yellow, uniform grease

-

Worked Penetration (1/4, 0.1 mm): 62

-

Dropping Point: 315 °C

-

Oil Separation (Pressure): 10.35 %

-

Evaporation Loss (200 °C, 1 h): 1.07 %

-

Copper Corrosion (T3, 100 °C, 3 h): Pass

-

Apparent Viscosity (–50 °C, 10 s⁻¹): 383 Pa·s

-

Oxidation Stability (0.78 MPa, 100 °C, 500 h): Pressure drop 0 kPa

Summary

The 7016 High & Low Temperature Lubricating Grease is a robust and reliable lubrication solution engineered for extreme temperature environments and high-demand applications. Its synthetic oil base, organic thickener system, high dropping point, and excellent oxidation resistance provide long-lasting protection for rolling bearings operating under thermal stress. Designed with aviation electrical machinery and high-temperature industrial equipment in mind, 7016 grease delivers consistent performance, reduced maintenance requirements, and enhanced operational safety, making it an excellent choice for critical lubrication applications where reliability is essential.

Reviews

There are no reviews yet.