7016-highlow-temperature-lubricating-grease

7016 High/Low Temperature Lubricating Grease

Wide-Temperature, High-Stability Grease for Precision and Aerospace Applications

SINOPEC 7016 High/Low Temperature Lubricating Grease is a premium-grade specialty grease developed for demanding applications that require reliable lubrication across an exceptionally wide temperature range. Formulated with a high-performance synthetic base oil thickened by an organic gelling agent, and enhanced with advanced oxidation-resistant additives, this grease is designed to deliver stable, long-lasting lubrication under extreme thermal, mechanical, and environmental conditions.

The formulation philosophy behind 7016 focuses on maintaining consistent lubricating performance where conventional greases fail. Whether operating in ultra-low temperatures or exposed to sustained high heat, the grease retains appropriate consistency, load-carrying capacity, and film strength, ensuring the protection and efficiency of precision bearings and rotating components.

Product Overview

7016 High/Low Temperature Lubricating Grease is engineered to meet the stringent requirements of aviation electrical equipment and high-temperature industrial machinery. Its synthetic oil base provides excellent low-temperature fluidity, while the organic thickener system ensures outstanding thermal resistance and structural stability at elevated temperatures. Carefully selected additives further enhance oxidation resistance, corrosion protection, and overall service life.

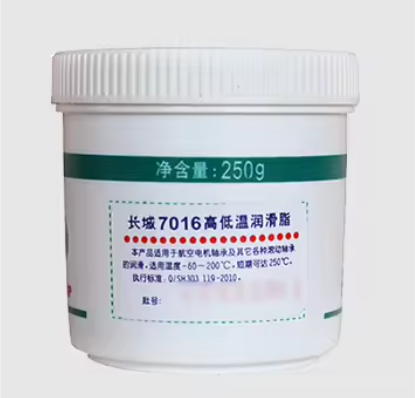

This grease complies with Q/SH303 119 technical standards, making it a reliable choice for critical applications where operational stability and lubrication integrity are essential.

Key Performance Features

Excellent High and Low Temperature Performance

7016 grease maintains effective lubrication across a wide temperature range from -60°C to 200°C, with the ability to withstand short-term exposure up to 250°C. At low temperatures, it exhibits low apparent viscosity, allowing bearings to start smoothly with minimal torque. At high temperatures, it resists softening, oil separation, and evaporation, ensuring continuous lubrication and reduced wear.

Outstanding Mechanical and Colloidal Stability

The grease demonstrates excellent resistance to mechanical shearing and structural breakdown during prolonged operation. Its superior colloidal stability ensures that the base oil and thickener remain uniformly dispersed, allowing precision bearings to remain fully lubricated even under high-speed or high-load conditions.

Strong Oxidation and Chemical Stability

With advanced antioxidant additives, 7016 grease effectively resists oxidation and degradation during long-term exposure to heat and oxygen. In high-pressure oxygen environments, it shows no measurable pressure drop over extended testing periods, indicating excellent chemical stability and extended service intervals.

Reliable Water Resistance

The grease provides dependable lubrication in humid or damp environments. Its strong resistance to water washout helps protect bearings from corrosion and lubrication failure, making it suitable for applications where moisture exposure is unavoidable.

Typical Technical Properties

-

Appearance: Light yellow, uniform ointment

-

1/4 Penetration (0.1 mm): 62

-

Drop Point: 315°C

-

Oil Separation under Pressure: 10.35%

-

Evaporation Loss (200°C, 1 hour): 1.07%

-

Copper Corrosion (T3, 100°C, 3 hours): Qualified

-

Apparent Viscosity (-50°C, 10 s⁻¹): 383 Pa·s

-

Chemical Stability (0.78 MPa O₂, 100°C, 500 hours): No pressure drop

These characteristics confirm the grease’s ability to maintain consistency, resist thermal degradation, and protect metal surfaces under severe operating conditions.

Applications

7016 High/Low Temperature Lubricating Grease is particularly suitable for:

-

Bearings in aviation electrical machines such as generators, motors, and inverter systems

-

Precision rolling bearings operating under high or fluctuating temperatures

-

Industrial equipment exposed to thermal cycling, high-speed rotation, or extended service periods

-

Applications requiring reliable lubrication at both extremely low startup temperatures and sustained high operating temperatures

Its balanced performance makes it an ideal choice for industries where lubrication failure is not an option.

Packaging and OEM Capability

The product is commonly supplied in 250 g plastic containers, with customized packaging available upon request. OEM branding is accepted, enabling distributors and equipment manufacturers to integrate the product seamlessly into their own product lines.

Storage and Handling Recommendations

To maintain optimal product performance, 7016 High/Low Temperature Lubricating Grease should be stored in a clean, dry environment away from direct sunlight. During storage and application, care should be taken to prevent dust or other contaminants from entering the grease. Before lubrication, bearing surfaces and components should be thoroughly cleaned and dried. The grease should not be mixed with other lubricants to avoid performance degradation.

Conclusion

SINOPEC 7016 High/Low Temperature Lubricating Grease represents a dependable lubrication solution for extreme and demanding environments. With its excellent thermal adaptability, mechanical stability, oxidation resistance, and water resistance, it delivers consistent protection for precision bearings and critical rotating components. Designed to perform where ordinary greases reach their limits, 7016 is a trusted choice for aviation, high-temperature industrial equipment, and other applications requiring uncompromising lubrication performance.

Reviews

There are no reviews yet.