sinopec-7011-low-temperature-extreme-pressure-grease

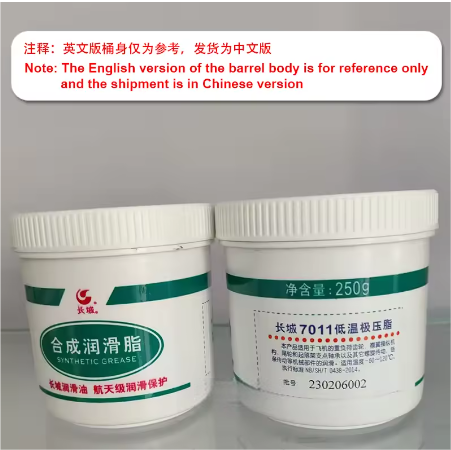

Great Wall 7011 Low Temperature Extreme Pressure Grease

Ultra-Low Temperature, Heavy-Load Protection for Aerospace and Precision Machinery

Product Overview

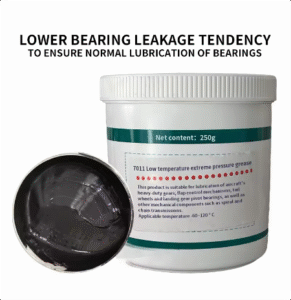

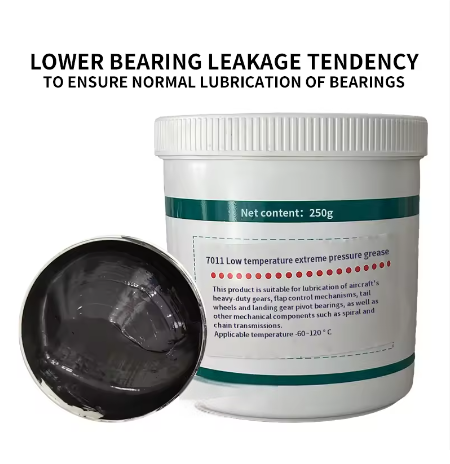

Great Wall 7011 Low Temperature Extreme Pressure Grease is a high-performance synthetic grease specifically engineered for applications requiring reliable lubrication under extremely low temperatures and heavy loads. Thickened with a soap-based thickener and fortified with molybdenum disulfide (MoS₂), antioxidant, rust inhibitor, and structural-improving additives, this grease delivers outstanding anti-wear, extreme pressure, and low-temperature performance.

Designed in compliance with SH/T 0438-92 (1998) and NB/SH/T 0438-2014, Great Wall 7011 is widely used in aerospace, aviation ground equipment, precision machine tools, and heavy-duty industrial transmissions, where conventional greases fail due to brittleness, oil separation, or insufficient load-carrying capacity at low temperatures.

Key Performance Advantages

Exceptional Low-Temperature Operability

Great Wall 7011 maintains excellent pumpability and lubrication film integrity down to –60 °C, ensuring bearings and moving parts operate smoothly in extreme cold environments without torque spikes or start-up failures.

Outstanding Extreme Pressure & Anti-Wear Protection

The inclusion of solid lubricant MoS₂ significantly enhances load-carrying capacity, effectively preventing metal-to-metal contact under shock loads, oscillating motion, and boundary lubrication conditions.

Superior Mechanical & Colloidal Stability

The grease exhibits excellent resistance to mechanical shear and oil separation, ensuring long service life and reduced grease leakage even under vibration or high centrifugal forces.

Low Oil Bleeding & Evaporation Loss

Carefully balanced base oil viscosity and thickener structure minimize oil loss at elevated temperatures, maintaining consistent lubrication performance throughout the operating range.

Excellent Corrosion & Oxidation Resistance

Advanced antioxidant and rust-preventive additives protect metal surfaces against oxidation, moisture ingress, and corrosion, extending component life in demanding service environments.

Typical Applications

Great Wall 7011 is recommended for lubrication of components exposed to extreme cold, heavy loads, or intermittent motion, including:

-

Aircraft heavy-duty gears

-

Flap control mechanisms

-

Tail wheels and landing gear pivot bearings

-

Screw drives and chain drives

-

Precision machine tool centers, tailstocks, and top pins during heavy cutting operations

-

Industrial equipment operating in cold regions or high-altitude environments

Operating Temperature Range: –60 °C to +120 °C

Typical Technical Data

| Property | Typical Value | Test Method |

|---|---|---|

| Appearance | Black homogeneous grease | Visual |

| Penetration (1/4 cone), 0.1 mm | 65 | GB/T 269 |

| Dropping Point, °C | 180 | GB/T 3498 |

| Copper Corrosion (100 °C, 3 h) | Pass | SH/T 0331 |

| Oil Separation, % (m/m) | 16.04 | GB/T 392 |

| Apparent Viscosity (–50 °C, 10 s⁻¹), Pa·s | 890 | SH/T 0048 |

| Evaporation Loss (120 °C), % | 0.65 | SH/T 0337 |

| Four-Ball EP (ZMZ), N | 763 | GB/T 3142 |

| Oxidation Stability (100 °C, 100 h), MPa | 0 | SH/T 0335 |

International Brand Equivalence & Spec Benchmarking

Great Wall 7011 is commonly positioned as a cost-effective alternative to internationally recognized low-temperature, MoS₂-containing extreme pressure greases used in aerospace and precision industries.

Performance Benchmark Table (Engineering Reference)

| Parameter | Great Wall 7011 | Klüber | Mobil | Shell |

|---|---|---|---|---|

| Typical Comparable Product | — | Klüberplex BEM 41-132 | Mobilgrease 28 | AeroShell Grease 33 |

| Base Oil Type | Synthetic oil | Synthetic oil | Synthetic oil | Synthetic oil |

| Thickener Type | Soap-based | Polyurea / special thickener | Clay (Bentone) | Lithium complex |

| Solid Lubricant | MoS₂ | MoS₂-free (EP additives) | MoS₂-free | MoS₂-free |

| NLGI Grade | Approx. 1–2 | 2 | 1 | 2 |

| Operating Temp. Range (°C) | –60 to +120 | –50 to +150 | –54 to +177 | –54 to +121 |

| Extreme Pressure Performance | Very High (MoS₂) | High | Medium-High | Medium-High |

| Aerospace Application Suitability | Yes | Yes | Yes | Yes |

| Positioning | High EP, low-temp, cost-efficient | Premium long-life | Premium aviation | Premium aviation |

Engineering Note:

While Mobilgrease 28 and AeroShell Grease 33 are widely used aviation greases, Great Wall 7011 offers stronger boundary lubrication and shock-load resistance due to MoS₂, making it particularly suitable for heavy-load gears, pivot points, and intermittent motion components in low-temperature environments.

Storage & Handling Recommendations

-

Store in a clean, dry, and shaded environment

-

Clean lubrication points thoroughly before application

-

Reseal packaging promptly after use to prevent contamination

Conclusion

Great Wall 7011 Low Temperature Extreme Pressure Grease delivers reliable lubrication under extreme cold and heavy load conditions, combining solid lubricant protection, excellent mechanical stability, and strong EP performance. It represents a technically competitive and economically attractive alternative to well-known international brands such as Klüber, Mobil, and Shell, particularly in aerospace ground equipment, precision machinery, and heavy industrial applications.

Reviews

There are no reviews yet.