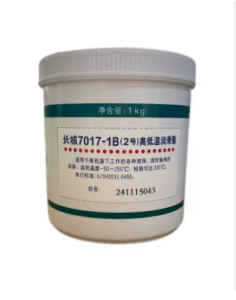

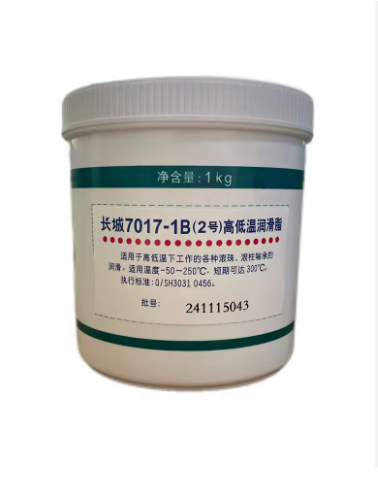

7017-1-high-and-low-temperature-grease

7017-1 High/Low Temperature Lubricating Grease

Extreme-Temperature, Long-Life Grease for High-Speed and High-Load Bearings

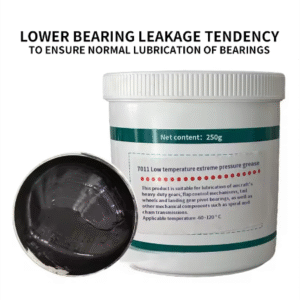

7017-1 High/Low Temperature Lubricating Grease is a premium specialty grease developed for bearings and mechanical components operating under extreme thermal conditions. Designed to perform reliably across a very wide temperature range, this grease combines excellent high-temperature resistance, strong oxidation stability, and dependable protection against moisture and corrosion. It is especially suitable for applications where operating temperatures exceed 200°C and where long service life and lubrication reliability are critical.

With a carefully balanced formulation, 7017-1 maintains structural integrity, lubricating film strength, and bearing protection under high-speed, high-load, and high-temperature conditions. Its performance makes it a dependable lubrication solution for aviation equipment, industrial machinery, and specialized high-temperature production processes.

Product Advantages

Outstanding High and Low Temperature Performance

7017-1 demonstrates excellent lubrication performance across an extended temperature range from -60°C to 250°C, with the ability to tolerate short-term exposure up to 280°C. Its particularly strong high-temperature performance allows bearings to operate reliably in environments where conventional greases rapidly degrade. Even under sustained heat, the grease resists softening, evaporation, and oil loss, significantly extending bearing service life.

Excellent Anti-Splashing and Water Resistance

The grease shows strong resistance to oil separation and splashing, making it suitable for use in damp or humid environments. This characteristic ensures that the lubricating film remains intact even in the presence of moisture, helping to prevent lubrication failure and reducing the risk of premature bearing wear.

Superior Oxidation Resistance

7017-1 is formulated with advanced antioxidant components that effectively slow oxidation under high-temperature conditions. This oxidation resistance ensures stable performance during long-term operation, minimizing grease hardening, sludge formation, and viscosity increase. As a result, equipment can operate for extended periods with reduced maintenance frequency.

Reliable Rust and Corrosion Protection

The grease provides effective rust prevention, forming a protective barrier on metal surfaces to shield bearing components from corrosion. This property is especially valuable in applications exposed to moisture, temperature fluctuations, or harsh industrial environments, where corrosion can severely shorten equipment lifespan.

Typical Technical Properties

7017-1 High/Low Temperature Lubricating Grease exhibits stable and well-balanced physical and chemical characteristics that support its performance in extreme conditions:

-

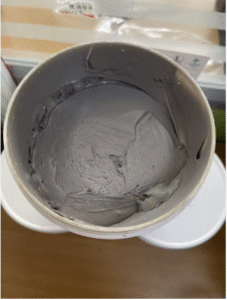

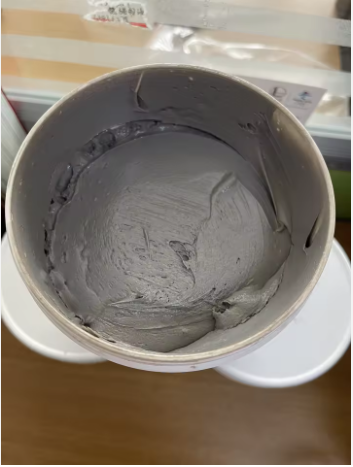

Appearance: Grey, uniform ointment

-

Drop Point: Above 330°C

-

1/4 Penetration (0.1 mm): 72

-

Evaporation Loss (200°C): 0.75% (m/m)

-

Oil Separation under Pressure: 7.34% (m/m)

-

Apparent Viscosity (-50°C, 10 s⁻¹): 1492 Pa·s

-

Copper Corrosion (T3, 100°C, 3 hours): Qualified

-

Chemical Stability (Oxygen Pressure 0.78 MPa, 100°C, 100 hours): No pressure drop

These properties confirm the grease’s ability to maintain consistency, resist thermal degradation, and protect metal surfaces under prolonged exposure to high temperature and mechanical stress.

Applications

7017-1 High/Low Temperature Lubricating Grease is suitable for a wide range of demanding applications where both high-temperature resistance and reliable lubrication are required.

It is particularly recommended for rolling bearings operating under high temperature, high speed, and extended temperature ranges exceeding 200°C, including but not limited to:

-

Aviation electric machines

-

Electric appliances and motors

-

Thrust bearings in clutch systems

-

High-temperature blowers and fans

-

Wheel bearings of racing cars

-

Bearings used in cold-region field operations requiring low-temperature start-up performance

In addition to bearing lubrication, 7017-1 is widely applicable in industrial equipment operating continuously under high-temperature environments, such as:

-

Plastic stretching machines

-

Polyester hot-setting machines

-

Resin finishing machines

-

Molten salt pump motors

-

Long-loop steamers

-

High-temperature dyeing vats

-

Decating machines

-

Shrinkage machines

In these applications, the grease provides stable lubrication, reduces friction and wear, and supports smooth equipment operation under severe thermal and mechanical conditions.

Service Temperature Range

-

Recommended operating temperature: -60°C to 250°C

-

Short-term maximum temperature: Up to 280°C

This wide temperature adaptability allows 7017-1 to meet the lubrication demands of both cold-start conditions and sustained high-temperature operation.

Conclusion

7017-1 High/Low Temperature Lubricating Grease is a high-performance solution engineered for extreme operating environments. With its excellent high-temperature stability, strong oxidation resistance, dependable water resistance, and effective corrosion protection, it ensures long bearing life and reliable equipment operation. Designed for aviation, automotive, and high-temperature industrial applications, 7017-1 delivers consistent lubrication performance where ordinary greases are unable to perform, making it a trusted choice for critical and demanding lubrication requirements.

Reviews

There are no reviews yet.