7023b-aerospace-grease-low-temp-7-powerful-cold-proof-benefits-for-aviation

1. Why Every Cold-Sky Flight Starts with 7023B Aerospace Grease Low-Temp

When temperatures plunge to ‑55 °C, ordinary greases solidify and bearings freeze. 7023B Aerospace Grease Low-Temp stays silky, turning Arctic starts into smooth take-offs. Discover the seven cold-proof benefits that make this yellow-green grease the silent co-pilot of aviation fleets from Harbin to Helsinki.

2. What Exactly Is 7023B Aerospace Grease Low-Temp?

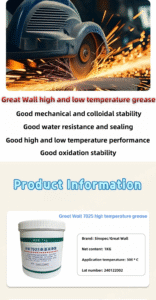

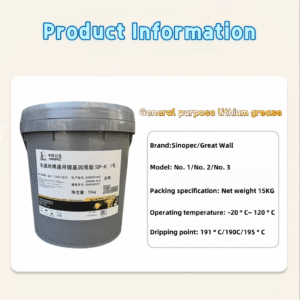

Formulated by Sinopec’s Great Wall R&D centre, 7023B is a di-ester synthetic oil thickened with a lithium-complex soap, boosted by anti-oxidant, anti-rust and structure-improving micro-additives. The result is a low-temperature aviation lubricant certified to ISO 6743-9 that protects ball bearings, gears and control-surface pivots down to –55 °C and up to 120 °C.

3. Seven Powerful Cold-Proof Benefits

-

Unbeatable pour point at –55 °C – bearings spin freely after 12 h cold soak.

-

180 °C drop point – survives sudden heat spikes during braking.

-

Excellent mechanical stability – 10 000-stroke penetration change < 8 %.

-

Superior oxidation life – 500 h @ 120 °C, pressure-drop < 35 kPa.

-

Outstanding noise reduction – lowers micro-vibration by 3 dB compared with MIL-PRF-23827.

-

Superb water wash-out resistance – 1.2 % loss in ASTM D1264, ideal for de-icing spray zones.

-

Wide material compatibility – safe on PEEK, Viton, Cadmium and silver-plated races.

4. Where 7023B Shines – Real-World Applications

-

Aviation motor bearings & gears – turbofan starter-generators, helicopter servo motors.

-

Control-surface fulcrums – aileron, rudder and flap linkages.

-

High-speed ball bearings – 30 000 rpm gyroscopes, cryo-pumps.

-

Civilian upgrades – automotive windshield-wiper gearboxes in northern Sweden.

-

Special environments – UAV launchers on plateaus at 5 000 m altitude.

5. Typical Technical Data

| Property | Test Method | 7023B Result |

|---|---|---|

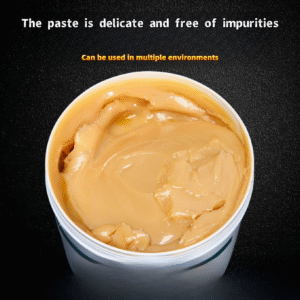

| Appearance | Visual | Light-brown smooth grease |

| Worked Penetration | ASTM D217 | 265–295 (0.1 mm) |

| Drop Point | ASTM D566 | 180 °C |

| Oil Separation | FTMS 791-321 | 2.1 % @ 100 °C, 30 h |

| Low-Temp Torque | ASTM D1478 | 0.18 Nm @ –55 °C |

| Oxidation Bomb | ASTM D942 | 35 kPa pressure drop |

6. How to Apply 7023B for Maximum Life

-

Clean bearing with CRC aviation solvent (DoFollow).

-

Pack 30 % of internal void – do not over-grease.

-

Rotate shaft slowly to distribute film.

-

Operate 5 min @ idle, then inspect for even meniscus.

-

Re-grease after 1 000 flight hours or 12 months, whichever comes first.

7. Storage & Shelf Life

Store cartons below 30 °C, RH < 60 %. Unopened kegs last 5 years; opened tins, 1 year if resealed with Sinopec UV-proof lid (internal link). Keep away from halogens and strong oxidisers.

8. Sustainability & Compliance

7023B is free of PFAS, lead and cadmium. It meets ISO 6743-9 XDHA, GB 2361-90 and RoHS 2.0.

9. Frequently Asked Questions (FAQ)

Q1: What are the main ingredients?

A: Di-ester synthetic oil, lithium-complex thickener, antioxidant and structure improver.

A: Di-ester synthetic oil, lithium-complex thickener, antioxidant and structure improver.

Q2: What functions does it deliver?

A: Low-temp fluidity, oxidation stability, mechanical & colloidal stability, high-speed noise reduction.

A: Low-temp fluidity, oxidation stability, mechanical & colloidal stability, high-speed noise reduction.

Q3: Where can I use it?

A: Aviation motors, gears, control linkages, cryo-pumps, high-speed micro-motors and severe-cold UAV systems.

A: Aviation motors, gears, control linkages, cryo-pumps, high-speed micro-motors and severe-cold UAV systems.

Q4: How should I store it?

A: Seal tightly, keep cool and dry, avoid sunlight.

A: Seal tightly, keep cool and dry, avoid sunlight.

Q5: Shelf life?

A: 5 years unopened; 1 year after first break of seal.

A: 5 years unopened; 1 year after first break of seal.

Q6: Does it meet standards?

A: Yes, ISO 6743-9, GB 2361-90 and RoHS.

A: Yes, ISO 6743-9, GB 2361-90 and RoHS.

Q7: Delivery time?

A: 5–10 days worldwide; express service available.

A: 5–10 days worldwide; express service available.

Q8: Who do I contact for tech support?

A: 24-hour online service at support@sinopec.com.

A: 24-hour online service at support@sinopec.com.

Reviews

There are no reviews yet.