b8d-turn-mill-lathe-4plus4-driven-tool-turret

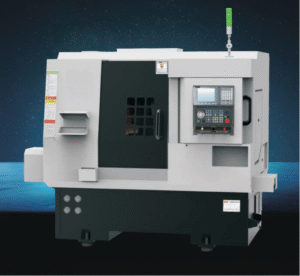

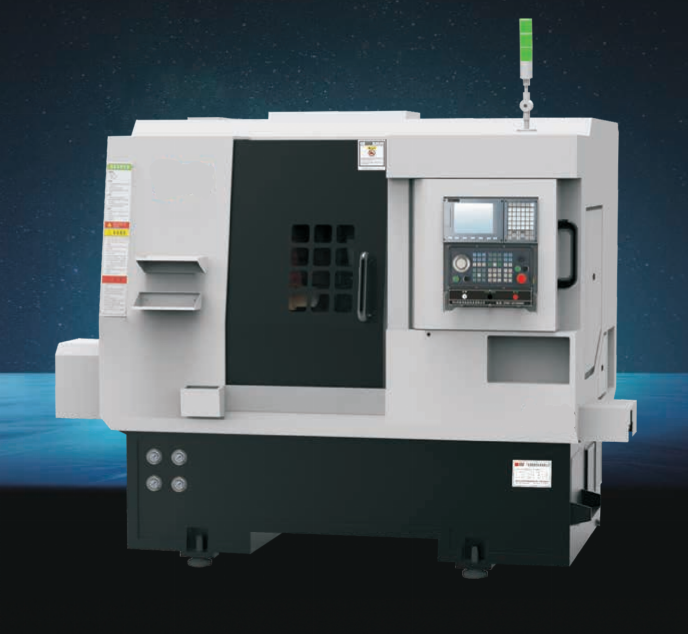

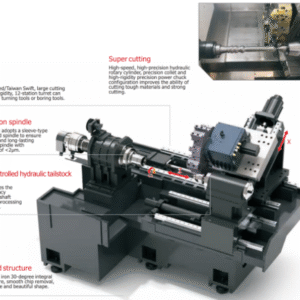

4+4 Driven Tool + Turret Turn-Mill Lathe – Model B8D

The B8D turn-mill center is an advanced multi-function CNC machine designed to complete complex machining tasks in a single clamping. Built for precision, flexibility, and efficiency, this machine combines turning, milling, and drilling capabilities to help manufacturers significantly reduce setup time and improve part accuracy. With its powerful Y-axis, high-speed live tooling, and industry-leading control systems, the B8D is an ideal solution for precision components in automotive, electronics, instrumentation, hardware, and general machinery sectors.

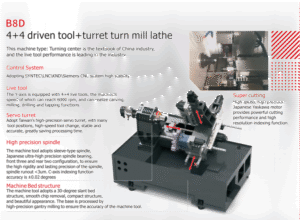

High-Efficiency Multi-Process Capability

The B8D is engineered as a true turning–milling center. It integrates multiple machining processes—turning, milling, drilling, tapping, and engraving—into one compact and stable platform. By completing multiple operations in a single clamping, the machine minimizes cumulative errors, shortens processing cycles, and maximizes throughput. This makes it especially suitable for complex components, small-batch production, and flexible manufacturing lines.

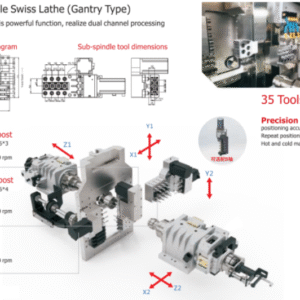

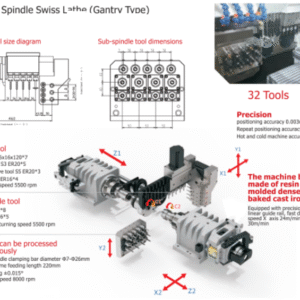

Powerful Y-Axis With Precision Engraving

The machine features a strong Y-axis travel of 230 mm, allowing for precise multi-surface machining and accurate off-center operations. The Y-axis is equipped with 4+4 live tools on both the end face and side positions, offering excellent flexibility for complex geometries. Japanese-made components are used for the live tooling system, ensuring low noise, long service life, and excellent rotational stability.

With a maximum live-tool speed of 6000 rpm, users can perform engraving, contouring, drilling, tapping, and light milling operations with ease. This level of performance makes the B8D a versatile and dependable machine for shops seeking higher productivity without sacrificing precision.

Industry-Leading Control Systems

The B8D supports multiple high-stability CNC control platforms, including:

-

SYNTEC 22TB

-

LNC

-

KND

-

Siemens

These systems deliver fast response times, superior interpolation accuracy, and excellent reliability for demanding machining applications. Operators benefit from intuitive programming, easy tool management, and precise motion control.

High-Precision Servo Turret

The machine adopts a Taiwan high-precision servo turret with 12 stations, enabling fast and stable tool changes. Its reliable locking mechanism ensures positional accuracy and reduces tool-change downtime. The combination of driven tools and the servo turret allows operators to switch between different processes rapidly, significantly reducing the overall machining cycle.

Robust Machine Bed and Structure

The B8D is constructed with a 30-degree slant bed design for smooth chip evacuation and superior ergonomics. The base and bed are processed using high-precision gantry milling equipment, ensuring long-term structural stability and machining accuracy. The compact footprint and reinforced structure give the machine excellent rigidity, vibration resistance, and thermal stability.

High-Precision Spindle

The spindle adopts a sleeve-type construction with Japanese ultra-high precision bearings in a front-three, rear-two configuration. This design ensures excellent rigidity, stability, and long-term precision.

-

Spindle runout: < 3 μm

-

C-axis indexing accuracy: ±0.02°

These specifications provide exceptional performance in high-precision contouring and synchronized milling operations.

High-Performance Motors and Components

To support demanding cutting conditions, the B8D uses Japanese Yaskawa motors, offering strong torque output, fast acceleration, and high-resolution indexing.

Key motor specifications include:

-

Main spindle motor: 11 kW

-

X-axis motor: 2.4 kW

-

Z-axis motor: 2.4 kW

-

Y-axis motor: 1.1 kW

-

Live tool motor: 1.3 kW

-

Turret motor: 750 W

This robust configuration ensures stable heavy cutting, smooth tool transitions, and precise multi-axis coordination.

Technical Specifications – Model B8D

| Category | Specification |

|---|---|

| Control System | SYNTEC 22TB |

| Spindle Type | A2-5 |

| Max. Bar Diameter | φ45 mm |

| Max. Rotation Diameter | φ350 mm |

| Max. Processing Length | 100 mm |

| X/Z Max. Travel Speed | 30 m/min |

| Y-Axis Max. Travel Speed | 24 m/min |

| Repeat Positioning Accuracy (X/Z) | 0.005 mm |

| Repeat Positioning Accuracy (Y) | 0.008 mm |

| X Travel | 700 mm |

| Z Travel | 330 mm |

| Y Travel | 230 mm |

| Turret | 12-station servo turret |

| Power Tools | ER25 (4+4) |

| Total Machine Power | 20 kW |

| Machine Size | 2190 × 1996 × 2100 mm |

| Machine Weight | 4.5 T |

Designed for Superior Productivity

With its high rigidity, fast tool changes, powerful cutting capability, and integrated turning–milling functionality, the B8D turn-mill center provides manufacturers with a competitive advantage. Its combination of accuracy, speed, and reliability makes it an indispensable machine for companies seeking to streamline production and improve machining quality.

Note: Technical parameters are subject to change without prior notice as improvements are made.

Reviews

There are no reviews yet.