cfg46-series-cnc-lathe-high-precision-turning-center

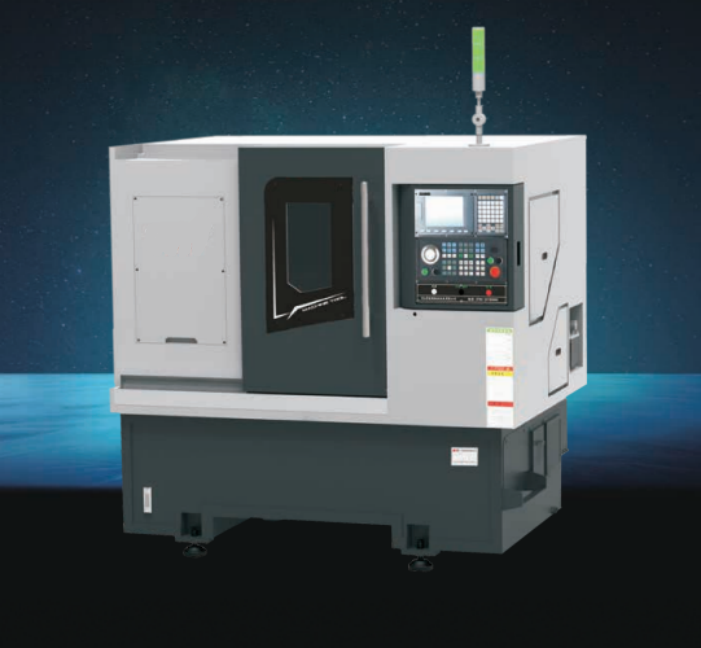

CFG46 / CFG46X-1 / CFG46X-2 High-Precision CNC Turning Center Series

The CFG46 Series CNC Turning Center is engineered to meet the modern manufacturing demands of high precision, high efficiency, and excellent machining flexibility. Designed with a compact footprint yet built with industrial-grade rigidity, the CFG46 series is ideal for machining small to medium-sized components across automotive, 3C electronics, aerospace fittings, and precision machinery parts. With a robust spindle, optional live tooling, precision installation technology, and a stable structural design, the CFG46 platform delivers consistent accuracy for both batch production and continuous operation environments.

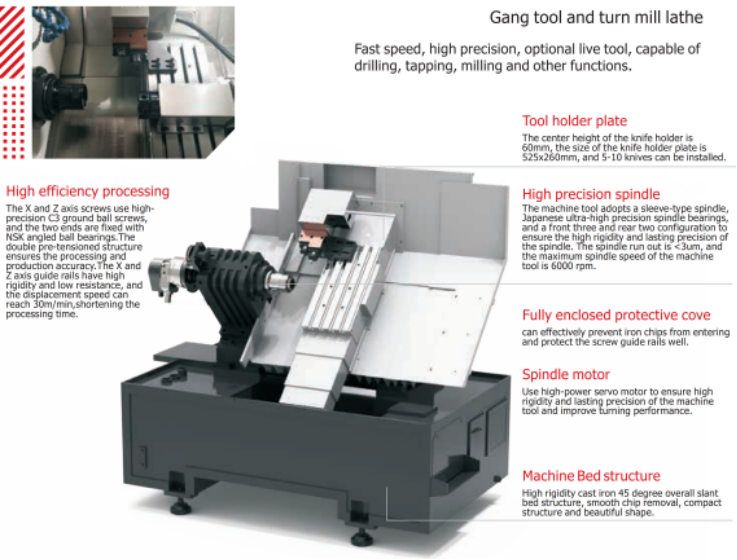

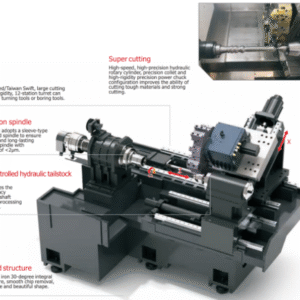

High-Precision Spindle and Structural Stability

At the core of the CFG46 series is a high-rigidity JSWAY-customized spindle matched with Taiwan Posa spindle technology. All models in this series utilize an A2-5 spindle nose, providing reliable compatibility with a wide range of collets and chucks. The spindle’s structure ensures excellent thermal stability and long-term performance, making it suitable for precision turning, facing, internal boring, and contour finishing.

With a maximum bar capacity of φ45 mm and a maximum rotation diameter of φ350 mm, the CFG46 provides generous capacity for complex geometries and mid-sized components. The high-performance 11 kW spindle motor enables powerful cutting, stability at high speed, and smooth transitions during machining. Combined with a compact overall structure, the machine supports both roughing and high-accuracy finishing applications.

Advanced Control with SYNTEC 22TA System

The CFG46 series adopts the popular SYNTEC 22TA control system, known for its intuitive interface, fast response, smooth interpolation, and stable operation. The controller features excellent compatibility for automation upgrades, live-tooling synchronization, and multi-axis machining cycles. It ensures stable performance even during high-speed contour cutting and multi-process execution.

Whether operated manually, semi-automatically, or integrated into a flexible automatic production line, the SYNTEC 22TA system supports efficient workflow and minimizes operator training time.

Precision Linear Motion and Fast Traversing Speeds

Accuracy and speed are crucial for modern machining. All three models—CFG46, CFG46X-1, and CFG46X-2—feature:

-

X/Z-axis rapid travel speed: 30 m/min

-

X-axis stroke: 720 mm

-

Z-axis stroke: 285 mm

These generously designed travel dimensions allow stable machining of face-type components and short-shaft parts while providing increased flexibility for tool approach and retreat.

The series offers repeat positioning accuracy of 0.005 mm, maintaining stable accuracy across long production runs. A secondary accuracy value, 0.008 mm, ensures long-term machining reliability under heavy usage.

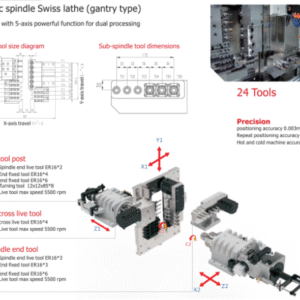

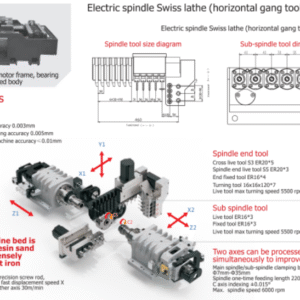

Enhanced Machining Flexibility with Live Tooling (CFG46X-1 / CFG46X-2)

The CFG46X-1 and CFG46X-2 models incorporate live tooling capability, powered by a 1.3 kW live tool motor. The addition of axial and radial powered tooling greatly expands machining capability, enabling:

-

Drilling

-

Tapping

-

Milling flats

-

Engraving

-

Slotting

This allows users to complete multiple machining processes in a single setup, reducing cycle time and improving productivity.

-

CFG46X-1: Equipped with ER25 live tooling system (1 position)

-

CFG46X-2: Upgraded to ER25 dual-position live tool configuration (2 positions)

These upgrades transform the machine from a standard turning center into a compact multi-function machining platform ideal for small part complexity.

Tooling Capacity and Adaptability

Each model supports 1–8 tool positions, providing flexibility for simple to moderately complex machining tasks. For typical production parts requiring turning, boring, grooving, chamfering, threading, and drilling, this configuration offers more than enough adaptability.

Combined with live tooling in the X-series models, the CFG46 platform becomes a cost-effective solution for high-mix, low-volume production or fast-cycle batch work.

Powerful Drive Motors and Energy Efficiency

The machine’s powertrain system is designed to support both performance and efficiency:

-

Spindle Motor: 11 kW (all models)

-

X-Axis Motor: 1.1 kW

-

Z-Axis Motor: 1.1 kW

The robust motors ensure smooth axis motion, fast tool positioning, and stable cutting forces. Total machine power varies between models:

-

CFG46: 15 kW

-

CFG46X-1: 17 kW

-

CFG46X-2: 19 kW

These configurations balance power output with energy efficiency, ensuring users achieve optimal machining force while minimizing operational costs.

Compact Layout and Industrial Durability

All three models share the same footprint—approximately 2100 × 1530 × 2000 mm—making the CFG46 series ideal for factories with space limitations or for integrating multiple machines into automated production cells. Despite the compact size, structural strength remains uncompromised, with a machine weight of 2.8 tons, providing rigidity, vibration resistance, and long-term reliability.

Consistent Accuracy for Demanding Industries

The CFG46 series supports industries that require:

-

High positioning accuracy

-

Stable long-term thermal behavior

-

Fast cycle times

-

Multi-process capability

-

Compact and rigid structure

From precision metal connectors to small automotive parts, electronic hardware, and instrument shafts, the machine excels in maintaining consistent quality across large production batches.

Conclusion

The CFG46 / CFG46X-1 / CFG46X-2 CNC Turning Center Series is a versatile, high-precision machining solution engineered for manufacturers who demand speed, rigidity, and high-accuracy performance. With its powerful 11 kW spindle, advanced SYNTEC control system, rapid axis movement, and compact yet rigid mechanical structure, it is capable of handling a wide variety of complex turning tasks. The X-series models further enhance capability with live tooling, making them ideal for multi-process machining in a single setup. Built for reliability and designed for modern production environments, the CFG46 series is a practical and efficient choice for precision machining facilities.

Reviews

There are no reviews yet.