cx400-cx600-power-turret-cnc-lathe

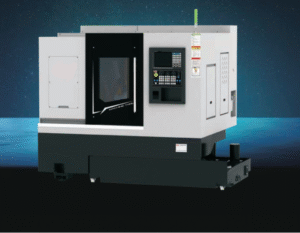

CX400 / CX600 Single-Spindle Power Turret CNC Lathe (Without Y-Axis)**

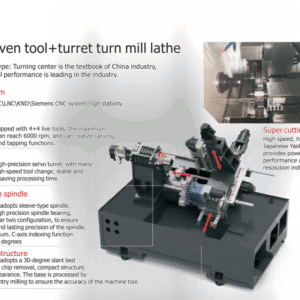

The CX400 and CX600 series single-spindle power turret CNC lathes are designed for heavy-duty machining, high-speed metal cutting, and precision milling operations required by modern manufacturing industries. Built around a high-rigidity cast iron 30-degree slant-bed structure, these machines deliver the perfect combination of strength, accuracy, and stability. With their powerful Jsway customized power turrets, high-performance sleeve-type electric spindles, and outstanding structural integrity, the CX series represents a versatile and cost-effective solution for machining complex disc parts and long shaft components in a single setup.

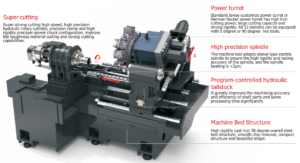

High-Performance Power Turret for Milling, Drilling, and Tapping

At the core of the CX400/CX600 is the standard Jsway customized power turret, engineered for large cutting capacity and exceptional rigidity. This heavy-duty turret supports 12 stations, each of which can be equipped with either 0-degree or 90-degree live tools. This flexibility enables comprehensive machining functions—including carving, milling, drilling, tapping, chamfering, and contouring—directly on the workpiece without secondary processes.

For customers requiring European-grade precision, the optional German Sauter power turret is available. Known for its longevity, stability, and thermal reliability, Sauter turrets further strengthen the machine’s cutting capability, especially in high-volume or demanding industrial applications.

Whether the task requires heavy milling cuts, rapid tool changes, or multi-step machining processes, the power turret ensures maximum cutting efficiency and significantly improves production throughput.

High-Rigidity 30° Cast Iron Slant-Bed Structure

The machine body adopts a one-piece high-rigidity cast iron bed with a 30-degree slant design. This provides several important advantages:

-

Smooth chip removal for increased processing stability

-

Compact and robust structure with enhanced vibration damping

-

Better accessibility for operators and automated loading/unloading

-

Improved lifespan and reliability of linear guideways and ball screws

This foundation is critical for maintaining precision during long and heavy machining cycles, especially when processing tough metals or oversized workpieces.

Ultra-High Precision Spindle (<2 μm Runout)

The CX series features Jsway’s customized sleeve-type electric spindle, engineered specifically for high rigidity and lasting accuracy. The spindle runout is controlled to <2 μm, ensuring exceptional surface finish, stable dimensional consistency, and accurate machining over long periods of use.

Two spindle configurations are available:

-

A2-5, 11 kW electric spindle

-

A2-6, 18.6 kW (or 22 kW for CX600) high-power spindle

The spindle can be indexed at 0.015°, enabling precise positioning for power-turret milling operations. Together with high-precision NSK/FAG P4 bearings, the spindle system delivers superb rotational stability even under heavy load or continuous high-speed cutting.

Superior Cutting Capability for Tough Materials

The machine is equipped with a high-speed, high-precision hydraulic rotary cylinder, precision clamp, and high-rigidity power chuck configuration. This combination greatly improves the cutting ability when machining stainless steel, alloy steel, forged parts, or other difficult materials.

With the CX series, operators can expect:

-

Strong cutting torque

-

High-speed chip removal

-

Excellent tool life

-

Exceptional stability during strong interrupted cutting

This makes the CX400/CX600 suitable for applications such as automotive components, aerospace fittings, hydraulic parts, precision mold accessories, and general industrial machining.

Efficient Linear Motion & Servo Control

Both X and Z axes achieve a maximum rapid traverse speed of 30 m/min, driven by high-precision servo motors. The use of precision ball screws and low-resistance guideways ensures smooth movement, high rigidity, and excellent positioning accuracy.

-

Repeat positioning accuracy: 0.005 mm

-

Optional high-power X-axis motor with brake for additional rigidity

-

Program-controlled hydraulic tailstock (standard)

The hydraulic tailstock significantly increases machining accuracy on longer shaft parts while reducing vibration, deflection, and processing time.

Automation Friendly & Wide Processing Adaptability

Thanks to its robust structure, power turret capabilities, and large spindle power options, the CX series can complete the machining of complex disc parts and long shaft components in a single clamping.

The design also supports robotic automation, such as:

-

Automatic loading/unloading

-

Gantry systems

-

Robotic arm integration

-

Automatic chip conveyors

This makes the CX400/CX600 ideal for mass production while maintaining high consistency and efficiency.

Compact, Beautiful, and Practical Machine Design

Despite their strong cutting capabilities, the CX400 and CX600 maintain a compact footprint and ergonomic design. Their slim yet rigid structure allows operators to work comfortably while maximizing workshop space utilization. With their clean protective enclosures and modern industrial styling, they deliver both professional appearance and operational convenience.

A Complete High-Performance Machining Solution

From the standard Jsway power turret to the high-precision sleeve spindle, from the cast iron slant-bed structure to the program-controlled tailstock, the CX400/CX600 power turret lathe series provides:

-

Strong cutting capability

-

High-speed machining

-

Heavy-duty structural rigidity

-

Long-term accuracy retention

-

Multi-function turning + milling capability

-

Large spindle power options

-

Reliable performance for both small and large batch production

Whether you process precision discs, flanges, sleeves, or long shafts, the CX series offers the accuracy, rigidity, and efficiency needed to meet today’s demanding industrial standards.

Reviews

There are no reviews yet.