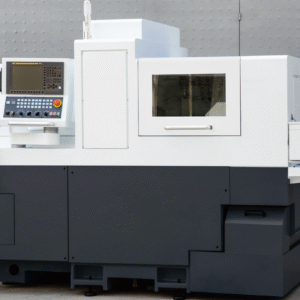

high-precision-cnc-turning-center-bf36-df36

High-Precision CNC Turning Center for 3C Electronics & LED Components

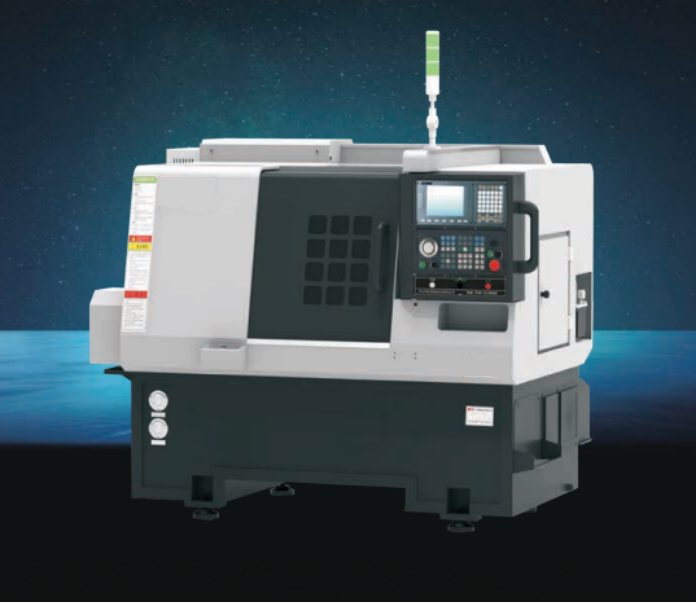

This advanced CNC turning center is engineered specifically for industries that demand extremely stable, microscale machining accuracy—such as LED manufacturing, mobile phone components, and other 3C electronic parts. With its superior mechanical structure, high-speed spindle, and optimized servo power system, this machine delivers consistent dimensional accuracy even under continuous hot and cold operation. The thermal stability of the entire system ensures that machining dimensions remain almost unchanged, making it ideal for high-volume, high-precision mass production.

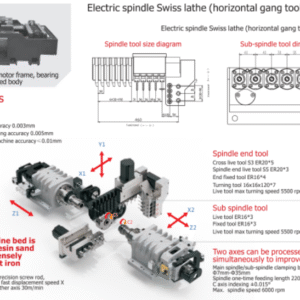

Stable Structure & Advanced Axis Technology

The X-axis and Z-axis adopt an advanced installation and alignment technology that significantly improves rigidity while reducing long-term wear. The screw guide rails are fully protected and not easily damaged, extending machine life and maintaining accuracy over years of operation. The axis transmission system achieves rapid movements of up to 36 m/min, allowing the machine to complete tasks faster while maintaining stable cutting performance.

(Factory setting: 30 m/min for stable continuous operation.)

For users who require enhanced vibration control and long-term geometric stability, the machine offers an optional heavy-duty casting base. Paired with the 30-degree slant bed structure, chip evacuation is smooth and unobstructed, ensuring clean cutting conditions and reducing heat accumulation.

High-Performance Spindle for Mirror-Level Cutting

At the core of this equipment is a high-precision sleeve-type spindle system, supported by Japanese ultra-precision bearings in a three-front, two-rear configuration. This design ensures extremely high rigidity, excellent support during deep cutting, and long-term precision retention.

-

Spindle runout: <3 μm

-

Maximum spindle speed: 6000 rpm

-

Cutting capability: Suitable for high-gloss finishing and fine surface machining

-

Material compatibility: Ideal for aluminum alloy, copper, stainless steel, titanium alloys, and general 3C structural parts

Beyond precision, the machine’s high-speed spindle allows manufacturers to achieve mirror-like surfaces and tight tolerances without extra finishing processes, significantly reducing production time.

High-Power Servo Motor System

To support heavy cutting and high-speed feeding, the machine is equipped with a 3.7 kW or 7.9 kW high-power spindle servo motor (depending on the model). The motor ensures strong torque during low-speed cutting and fast acceleration during high-speed operations.

The X-axis and Z-axis are driven by 1.1 kW servo motors, offering smooth movement and efficient power application for demanding precision machining tasks.

This high-power configuration makes the machine a high cost-performance choice—offering stronger output, higher efficiency, and better durability compared to similar machines at the same price point.

Enclosed Protective Cover & Long-Term Durability

The machine is equipped with a fully enclosed protective cover, which blocks flying chips, coolant splash, and airborne particles. This design provides three major advantages:

-

Protects guide rails and ball screws

-

Extends the service life of critical components

-

Improves operator safety and keeps the workplace clean

This ensures the machine maintains precision while also lowering maintenance cost.

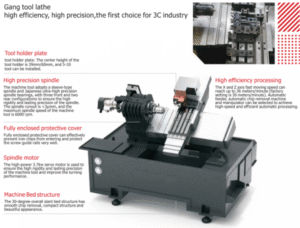

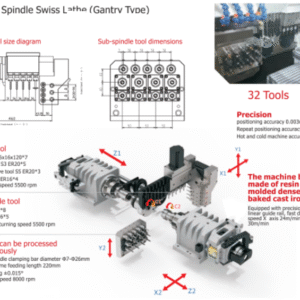

Tool Holder Plate — Flexible Tooling Options

The tool holder is designed for versatility and convenience, featuring:

-

Center height: 39 mm / 60 mm

-

Tool capacity: 5–10 tools

-

Stiff and durable plate design for stable multi-tool operations

This layout supports complex part machining, multi-step processes, and small-batch customization needs.

High-Efficiency Automatic Production Ready

To support modern automated manufacturing, the machine can be equipped with:

-

Automatic feeder

-

Automatic chip conveyor

-

Robotic manipulator

With these components, the entire machining line can achieve continuous high-speed automatic production, dramatically increasing efficiency and reducing labor involvement.

This makes the machine especially suitable for LED parts factories, smartphone component suppliers, and precision machining workshops with large daily output.

Technical Specifications

Model Options

-

BF36

-

DF36

-

DF36X

Control System

-

SYNTEC 22TA series

Processing Range

-

Max bar diameter: φ35 mm

-

Max rotation diameter: φ280 mm

-

Maximum processing length: 100 mm

-

Center height: 39 mm

Travel & Accuracy

-

X-axis travel: 760 mm

-

Z-axis travel: 300 mm

-

X/Z-axis travel speed: 30–36 m/min

-

Repeat positioning accuracy: 0.005 mm

Motor Power

-

Spindle motor: 3.7 kW / 7.9 kW

-

X-axis motor: 1.1 kW

-

Z-axis motor: 1.1 kW

-

Power head motor (DF36X): 1.3 kW

Other Data

-

Total machine power: 6.4 kW

-

Machine size: 2000 × 1402 × 1750 mm

-

Machine weight: 2.3 tons

Conclusion

With its high-speed spindle, thermal stability, durable axis design, and automation-ready structure, this turning center stands out as a high-efficiency, high-precision, cost-effective machine. It is built to meet the strict requirements of modern 3C electronics manufacturing, making it one of the most reliable and versatile choices for factories producing LED components, smartphone parts, and other high-precision mechanical components.

Reviews

There are no reviews yet.