lithium-grease-1-2-3-all-season

The General Purpose Lithium Base Grease is a high-performance multipurpose industrial lubricant formulated with premium base oils and thickened with high-quality lithium soap. Manufactured under strict quality control and aligned with SAE standards, this grease series offers exceptional versatility and durability for a wide range of mechanical applications. Available in multiple NLGI grades—NLGI 00, 0, 1, 2, and 3—it provides the flexibility to match different machinery requirements, operating speeds, and temperature conditions.

This lithium base grease stands out for its balanced mechanical stability, oxidative resistance, and high-temperature performance, making it suitable for both light-duty and heavy-duty industrial environments. Whether used in automotive bearings, electric motor housings, construction equipment, metallurgical machinery, agricultural tools, or general plant lubrication points, the formulation ensures long-lasting protection and lubrication reliability.

One of the primary strengths of this grease lies in its excellent structural stability. With worked cone penetration values ranging from 310–340 (NLGI 1), 265–295 (NLGI 2), and 220–250 (NLGI 3), the grease maintains a stable and consistent texture even after long-term mechanical shear. The extended working penetration after 100,000 strokes remains tightly controlled—≤380, ≤350, and ≤320 respectively—indicating minimal softening during continuous load cycles. This stability ensures that the grease stays in place, provides an even lubricating film, and does not leak or thin out prematurely during operation.

In terms of temperature resistance, the grease features a high dropping point of 175–180°C, depending on the grade. This enables secure lubrication performance in elevated temperature environments while preventing breakdown, thinning, or grease loss. Combined with an oxidation stability pressure drop of ≤0.070 MPa, it effectively resists oxidation and thermal degradation over long working cycles.

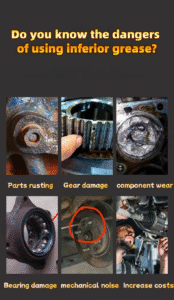

Corrosion protection is another key advantage. The grease passes copper corrosion testing (100°C for 24 hours), showing no green or black discoloration, which indicates excellent compatibility with copper and nonferrous metals. Additionally, with corrosion resistance at 52°C for 48 hours rated at ≤1, the product protects bearing surfaces and metal components from rust, chemical attack, and moisture-induced corrosion. This performance makes it suitable for humid environments, outdoor machinery, and equipment stored for prolonged periods.

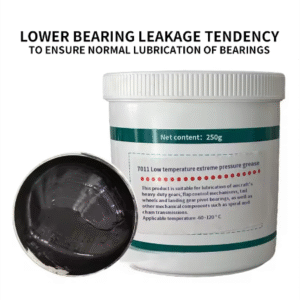

The grease also demonstrates low oil separation levels, with steel mesh oil separation of ≤10% for NLGI 1 and ≤5% for NLGI 2 and 3, ensuring minimal leakage and strong retention of lubricating oil within the thickener structure. The evaporation loss is maintained at ≤2.0%, further contributing to long-term lubrication performance and resistance to volatilization at elevated temperatures.

In cold temperatures, the grease maintains excellent pumpability and viscosity stability. With similar viscosity values at –15°C (10 s⁻¹) of 600 Pa·s, 800 Pa·s, and 1000 Pa·s for grades 1, 2, and 3 respectively, it ensures smooth operation and reduced torque requirements for machinery exposed to low-temperature environments.

Other advantages include strong water resistance, with leaching loss at ≤8%, indicating strong performance under moisture, rain, or water splashing conditions. This ensures suitable application for outdoor equipment, agricultural implements, and general machinery exposed to wet conditions.

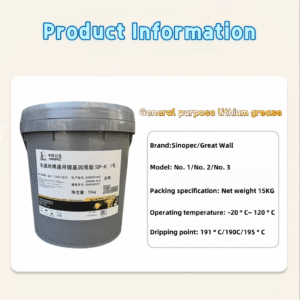

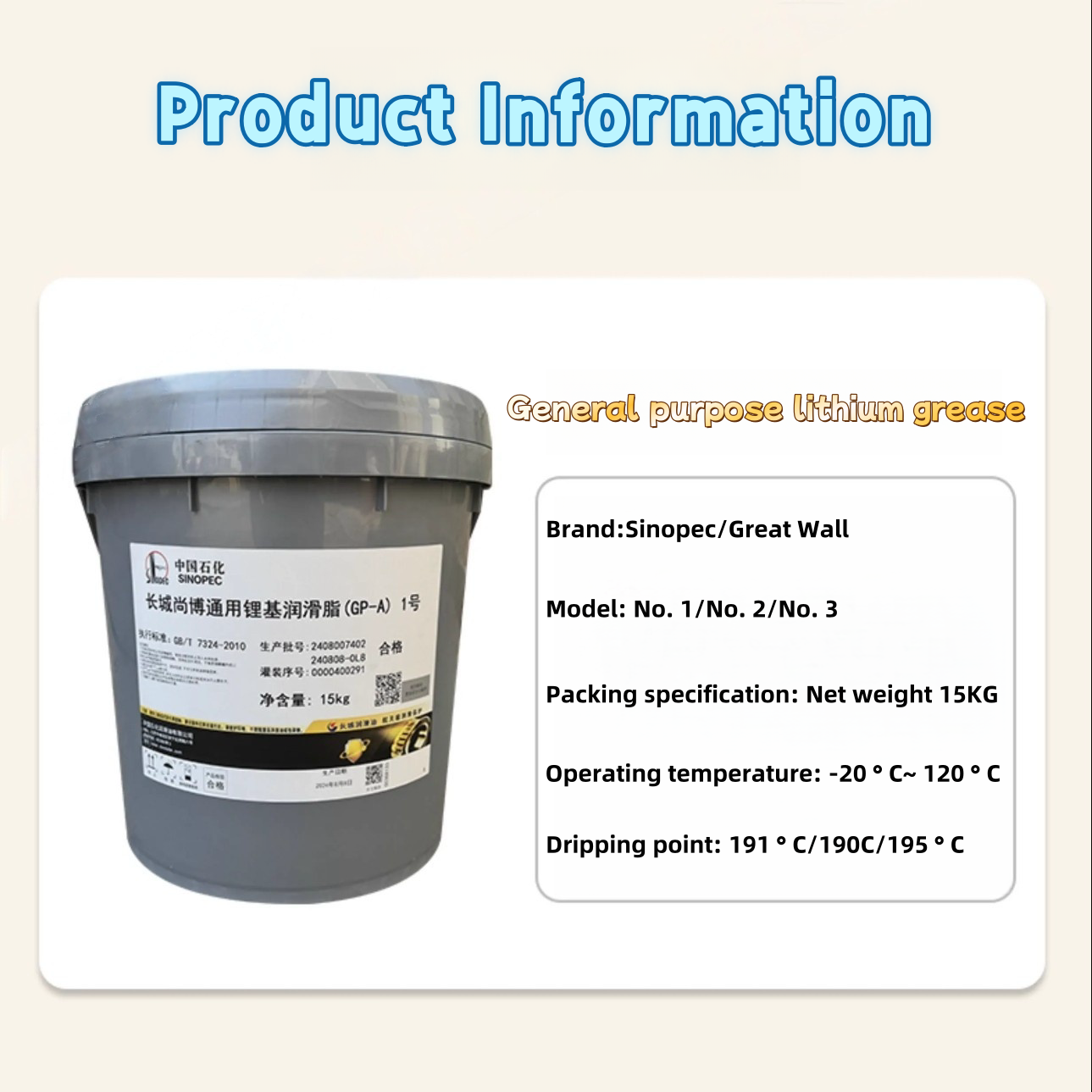

With its light yellow to brown smooth cream appearance, the grease is easy to identify and apply during maintenance operations. Packaged in 15 kg pails or 175 kg barrels, it is suitable for both end-users and industrial distributors. The product carries MSDS certification, ensuring compliance with international safety standards for handling, storage, and use.

The General Purpose Lithium Base Grease is designed to deliver long service life, high reliability, and consistent protective performance across multiple industries. Whether for daily factory maintenance or high-load industrial machinery, its formulation ensures stable lubrication, reduced friction, extended equipment life, and minimized downtime.

Reviews

There are no reviews yet.