m46-high-precision-turning-center

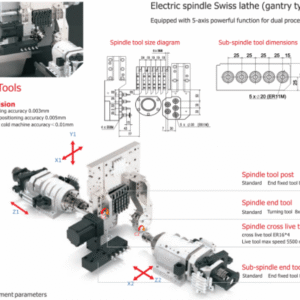

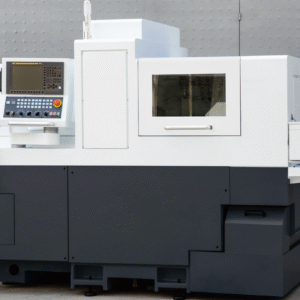

Product Description – M46 / M46X-1 / M46X-2 High-Precision CNC Turning Center

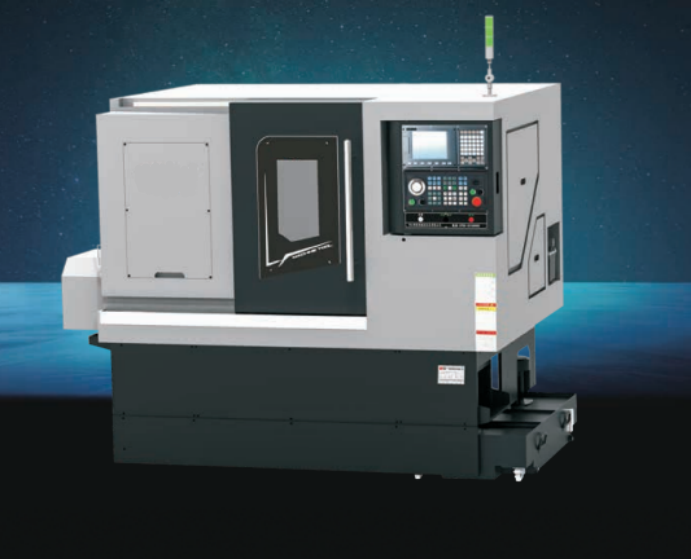

The M46 series high-precision CNC turning centers are engineered for users who demand fast cutting speed, high machining accuracy, long-term stability, and excellent durability. Built with a robust integral casting bed, powerful spindle options, and advanced servo drive systems, this machine series delivers outstanding performance in medium-to-heavy precision machining applications. Whether processing steel, stainless steel, copper, aluminum, or engineering alloys, the M46 family provides the rigidity, efficiency, and accuracy required for modern manufacturing.

High-Strength Z-Axis with Large Screw Rod

The Z-axis adopts a large M46–40mm high-strength screw rod, providing exceptional thrust and rapid response during machining. This oversized screw rod design greatly enhances cutting force output, accelerates positioning speed, and improves long-stroke machining stability. Even under heavy cutting or long-term continuous operation, the Z-axis maintains consistent accuracy with minimal thermal drift.

Fully Enclosed Protection – Waterproof, Chip-Proof, and Low Maintenance

The machine tool is designed with a full protective enclosure, ensuring absolute waterproofing and chip protection. This keeps cutting fluid, swarf, and debris away from the screw rods and guide rails, significantly extending component life and reducing maintenance frequency. The interior offers a large and practical workspace, allowing operators to easily load materials and manage machining tasks.

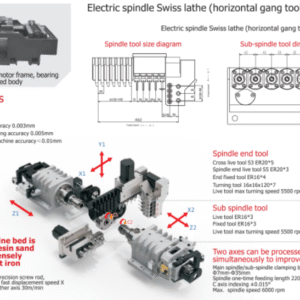

High-Speed Spindle Capable of High-Gloss Cutting

Equipped with a high-precision spindle structure, the machine supports speeds up to 6000 rpm, enabling high-gloss machining and ultra-smooth surface finishing. Customers can select between a 46-type or 56-type spindle, depending on the required rigidity and bar-feeding capacity. This flexible configuration makes the M46 series suitable for industries requiring precision profiles, mirror-like surfaces, or rapid cycle times.

Thermal Stability – Cold & Hot Machine Accuracy Remains Consistent

The machine’s structural components, spindle bearings, and screw design work together to ensure excellent thermal stability. Dimensional deviation between cold and hot states is extremely small, enabling the machine to maintain consistent tolerances even during long machining shifts.

High-Speed Feed – Up to 36 m/min

The maximum processing feed speed reaches 36 meters per minute, delivering shorter cycle times and higher throughput. The X and Z axes use high-precision C3 ground ball screws, mounted on both ends with NSK double-preloaded angular contact bearings, ensuring excellent rigidity and repeatability.

The guide rails offer high stiffness and low friction, enabling a rapid traverse speed of 30 m/min, significantly reducing non-cutting time.

Ultra-Stable Sleeve-Type Spindle

The spindle adopts a sleeve-type construction paired with Japanese ultra-precision spindle bearings—three bearings in the front and two in the rear. This arrangement provides high rigidity, excellent vibration suppression, and long-term stability. The spindle runout is controlled to <3 μm, ensuring superb cutting precision and surface quality.

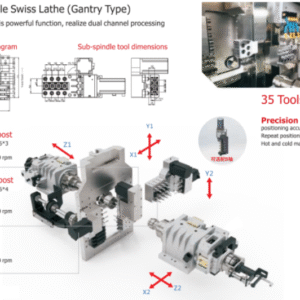

Flexible Tooling Capacity

The tool post plate supports a center height of 39mm or 60mm, accommodating 5–10 tools depending on the configuration. The M46X-1 and M46X-2 models include live tooling capabilities, enabling drilling, tapping, and milling operations in a single clamping. This multi-tasking capability greatly enhances processing efficiency and reduces fixture changes.

High-Power Main Motor

The machine can be equipped with:

-

5.5 kW / 7.5 kW servo motor

-

Optional 11 kW 46-type electric spindle

These power options guarantee strong torque output, rapid acceleration, and reliable long-term spindle performance.

45-Degree High-Rigidity Slant Bed

The machine bed features a 45° slant-bed structure, made from high-rigidity cast iron. This provides:

-

Excellent vibration absorption

-

Smooth and efficient chip evacuation

-

A compact and ergonomic machine layout

The slant-bed design also contributes to tool-life stability and high-precision cutting.

Technical Specifications (M46 Series)

| Model | M46 | M46X-1 | M46X-2 |

|---|---|---|---|

| Control System | LNC / SYNTEC 22TA | 22TA | 22TA |

| Spindle Nose | A2-5 | A2-5 | A2-5 |

| Max. Bar Diameter | φ45mm | φ45mm | φ45mm |

| Max. Rotation Diameter | φ350mm | φ350mm | φ350mm |

| Max. Processing Length | 100mm | 100mm | 100mm |

| Rapid Feed (X/Z) | 30m/min | 30m/min | 30m/min |

| Repeat Positioning Accuracy (X) | 0.005mm | 0.005mm | 0.005mm |

| Repeat Positioning Accuracy (Z) | 0.008mm | 0.008mm | 0.008mm |

| Center Height | 60mm | 60mm | 60mm |

| Travel (X / Z) | 840mm / 280mm | 840mm / 280mm | 840mm / 280mm |

| Spindle Motor | 11 kW | 11 kW | 11 kW |

| Live Tool Motor | — | 1.3 kW | 1.3 kW |

| Tool Capacity | 1–8 | 1–8 | 1–8 |

| Live Tools | — | ER25×1 | ER25×2 |

| Total Power | 14 kW | 16 kW | 18 kW |

| Machine Size | 2200 × 1640 × 2000 mm | ||

| Machine Weight | 3.3T |

Reviews

There are no reviews yet.