max-machining-diameter-o12o20-3-axis-swiss-lathe-d123d203

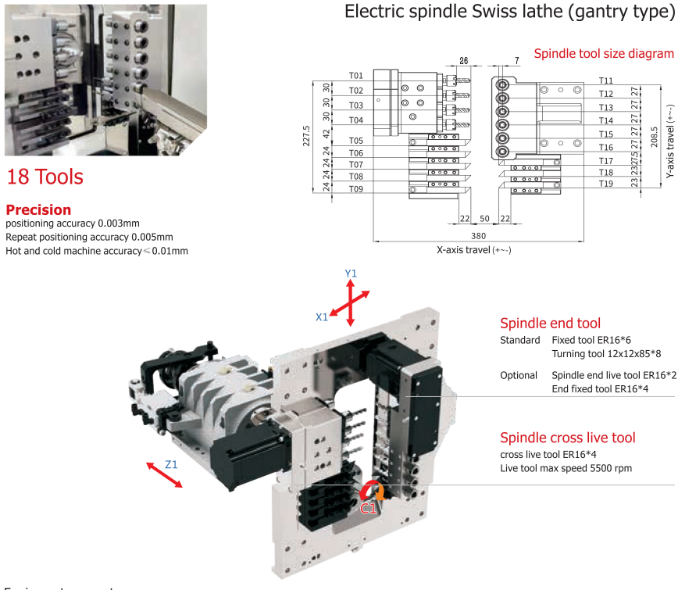

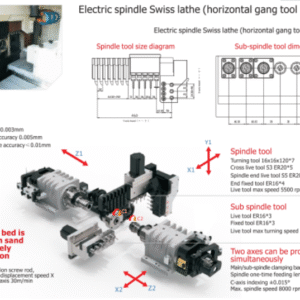

Electric Spindle Swiss Lathe (Gantry Type)

The Electric Spindle Swiss Lathe (Gantry Type) represents a new generation of precision turning equipment engineered for high-efficiency, high-rigidity, and high-accuracy machining applications. Built around an independently developed high-power synchronous electric spindle, this machine delivers rapid acceleration, smooth deceleration, and outstanding continuous torque output—ensuring excellent machining performance across complex and demanding operations.

Equipped with either FANUC 3.7 kW / SYNTEC 7.5 kW electric spindle systems, the lathe provides operators with strong cutting capability, superior speed response, and long-term reliability. The spindle system is specially optimized for Swiss-type cutting where consistent stability and concentricity are critical, making it ideal for machining precision components for electronics, automotive, aerospace, instruments, watch parts, and small-diameter precision molds.

A major highlight of this model is the in-house designed power head, engineered with low vibration, strong rigidity, and exceptional precision. This power head design reaches the technical level commonly associated with Japanese and European premium brands. Low noise operation, smooth power transmission, and long service life provide operators with an elite machining experience while minimizing downtime and maintenance costs.

From the outside, the machine showcases a modern and streamlined appearance with clean contours and refined craftsmanship—reinforcing its high-end brand positioning. Internally, the lathe adopts a highly rigid gantry structure that ensures excellent thermal stability and mechanical rigidity during long machining cycles.

The machine is equipped with a powerful 3-axis configuration, delivering ultra-efficient performance for turning, drilling, tapping, and milling operations. Both the X, Y, and Z axes adopt large-inertia servo motors (850W/750W), providing high torque, stable feed motion, and exceptional responsiveness. Each axis is supported by a double-nut ball screw and a robust bearing fixation method to maintain high accuracy throughout heavy-duty machining.

The precision-ground guide rails measure 25 mm, and the lead screw pitch is 10 mm, allowing a rapid traverse speed of 30 m/min, significantly improving cycle time and productivity. This combination of wide guide rails and high-capacity servo motors ensures continuous machining reliability even during fast feeds and deep cutting operations.

For tooling flexibility, the machine includes a standard S3 power head and supports optional S5 driven tools depending on specific production needs. This expands its ability to perform multi-functional compound operations without additional setups. Multiple ER16 and ER11 tool holder configurations allow flexible arrangements for front machining, cross live tooling, or milling procedures.

The model is available in two configurations—D123 and D203—covering bar diameters from 2–12 mm and 3–20 mm respectively. Both versions share identical machine footprints, enabling easy installation in compact workshops. Despite its compact size, the machine weighs 1300 kg, providing a stable cutting platform and excellent vibration absorption.

With its high-power electric spindle, advanced gantry structure, in-house precision power head, and high-rigidity motion system, this Swiss-type lathe is engineered to deliver high productivity, extreme durability, and excellent machining accuracy—making it a premium solution for industries requiring fast, stable, and high-precision small-diameter component production.

Reviews

There are no reviews yet.