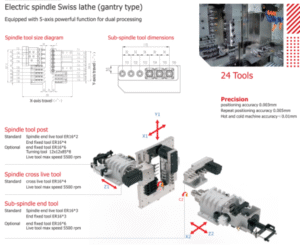

max-machining-diameter-o12o20-5-axis-swiss-lathe-d125d205

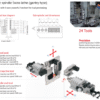

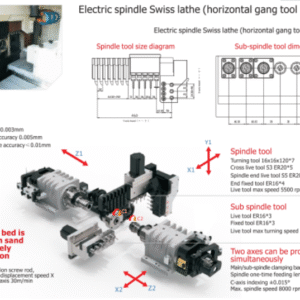

D125 / D205 Electric Spindle Swiss Lathe (Gantry Type) – High-Precision CNC Turning for Complex Small Parts

The D125 / D205 Electric Spindle Swiss Lathe is an advanced, gantry-type CNC turning center designed for high-precision machining, ultra-stable performance, and long-term reliability. Engineered with a temperature-compensated structure and dual-channel operation, this model is purpose-built for modern mass production needs in electronics, medical devices, automotive parts, connectors, precision shafts, instrument components and other industries requiring extreme accuracy and complex machining capabilities.

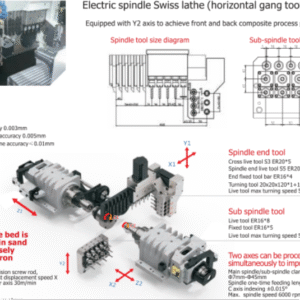

Integrates independently developed high-power synchronous electric spindles, available in multiple rated configurations—including FANUC 2.2 kW, SYNTEC 5.5 kW, and FANUC 3.7 kW / SYNTEC 7.5 kW for the 20-spindle variation—ensuring consistent power delivery for both the main spindle and sub-spindle. The fast acceleration and deceleration response delivers outstanding efficiency, especially for short-cycle, multi-step machining. This enables the D125/D205 to rival premium Japanese and European Swiss-type CNC machines while maintaining excellent cost-performance advantages.

High-Power Electric Spindle with Temperature Compensation

The machine is equipped with self-developed synchronous electric spindle system, designed to maintain stable performance even during long machining cycles where heat buildup commonly affects precision. The temperature-compensated mechanism automatically stabilizes spindle expansion, ensuring consistent accuracy, lower thermal deformation, and superior dimensional control.

Both models provide seamless synchronization between main and sub-spindles, enabling simultaneous turning, drilling, and tapping operations for maximum throughput.

Industrial-Grade Driven Tool System for Maximum Versatility

The independently developed S3, S4, and S5 driven tool systems offer low-noise operation, high rigidity, and exceptional machining accuracy. These attributes allow for powerful cross-drilling, milling, and tapping capabilities—all critical for multi-process production within a single setup.

Each driven tool station is engineered to deliver stable torque and minimal vibration, making it suitable for heavy-duty cutting, micro-machining, and high-speed fine drilling. The 3-way tool layout enhances tool utilization and supports complex part geometries.

Rigid Mechanical Structure & High-Speed Servo System

The D125 / D205 features a highly integrated, one-piece cast structural frame that combines the machine bed, motor base, bearing housings, and sub-spindle carriage. This monoblock design dramatically increases rigidity and improves vibration damping, leading to better surface finish, sustained accuracy, and extended tool life.

The X/Y/Z axis motors use 850W / 750W high-inertia servo motors, offering smooth and stable movement even in high-speed machining environments. Additionally, the double-nut ball screw design, together with the 25 mm linear guide, provides exceptional stiffness for demanding cutting operations.

High-Speed Machining Performance

With a 10 mm pitch screw and an impressive 30 m/min rapid travel, the machine supports fast tool changes and efficient multi-axis coordination. Whether producing small batches or long-running mass production jobs, the D125 / D205 delivers a high-efficiency workflow and reduced cycle times.

Tooling Flexibility for Complex Machining

The machine includes a full set of flexible tooling configurations:

-

8 pcs 12×12 mm turning tools

-

4 ER16 side live tools

-

4 ER16 fixed + 2 ER16 live spindle end tools

-

3 ER16 fixed + 3 ER16 live sub-spindle end tools

This allows the machine to complete turning, milling, drilling, tapping, grooving, and deburring without secondary operations.

Applications

The D125 / D205 electric spindle Swiss lathe is ideal for:

-

Precision medical components

-

Connector pins & micro-shafts

-

Auto parts & sensor housings

-

Electronic hardware

-

High-accuracy instrument parts

-

Mass-production small turned components

Reviews

There are no reviews yet.