max-machining-diameter-o12o20-6-axis-swiss-lathe-d126d206

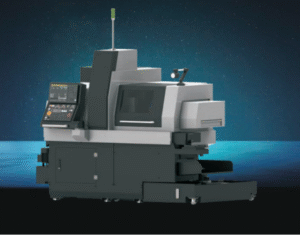

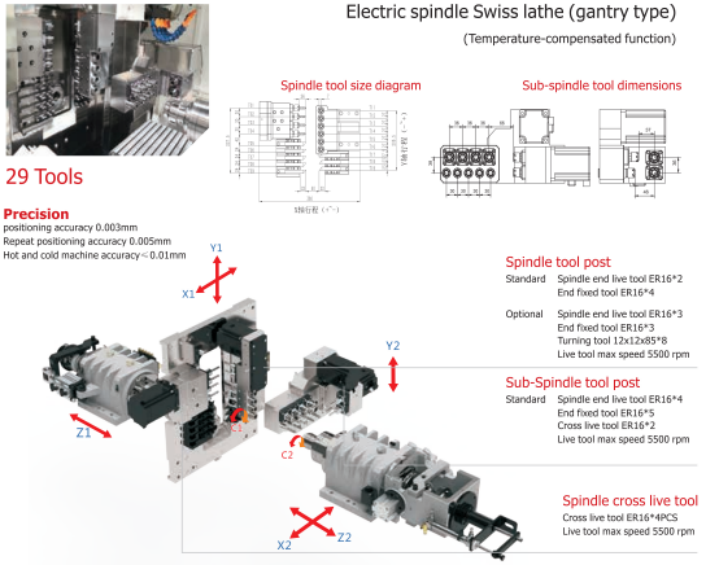

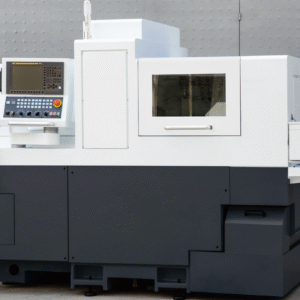

D126 / D206 Electric Spindle Swiss Lathe (Gantry Type)**

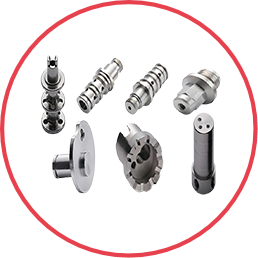

The D126 and D206 Electric Spindle Swiss Lathes represent JSWAY’s latest generation of high-performance, high-precision CNC turning equipment, designed specifically for demanding applications in medical device machining, automotive components, electronics hardware, instrumentation parts, aerospace connectors, and other industries requiring ultra-stable accuracy and long-term production reliability.

Built on a rigid gantry-type one-piece mechanical architecture, the machine bed, motor frame, bearing seats, and sub-spindle carriage are all integrally cast and machined as a single structure. This dramatically improves rigidity, minimizes vibration, and ensures long-term geometric stability. Combined with a refined exterior design, precise workmanship and a clean, professional appearance, the D126/D206 series delivers the high-end brand image associated with top Japanese and European Swiss-type machines.

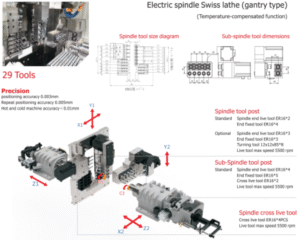

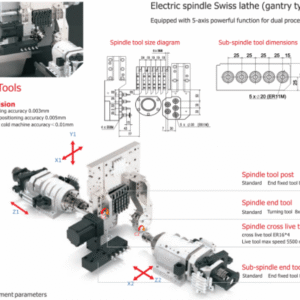

At the heart of the system is JSWAY’s independently developed temperature-compensated synchronous electric spindle, available in multiple performance configurations. For 12-spindle models, customers can choose FANUC 2.2 kW or SYNTEC 5.5 kW, while the higher-torque 20-spindle version offers FANUC 3.7 kW or SYNTEC 7.5 kW. No matter which configuration is selected, the main and sub-spindle power remain consistent, enabling perfectly balanced cutting conditions for both front and back machining operations. The spindles provide rapid acceleration and deceleration, high response speed, and excellent thermal performance—ensuring long-term accuracy even during high-speed continuous production.

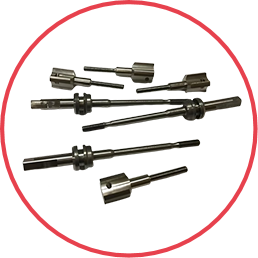

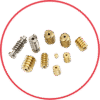

To complement the spindle capability, JSWAY also independently developed a new generation of low-noise, high-rigidity, high-precision driven tools, representing the highest level of the domestic industry and competitive with premium European and Japanese brands. For maximum flexibility, the platform supports S3, S4, and S5 driven tool positions, enabling more complex multi-process machining in a single setup.

The D126 and D206 machines adopt a full 6-axis configuration, offering a true ultra-efficient multitasking machining mode. Both X, Y, and Z axes are equipped with high-power 850 W / 750 W large-inertia servo motors, delivering excellent torque and rapid feed response. The ball screw adopts a double-nut design to maintain high cutting rigidity, while the bearing positioning method ensures stable accuracy during long-term operations. A 25 mm linear guideway combined with a 10 mm lead ball screw provides extremely fast response, allowing the carriage table to reach 30 m/min rapid travel speed.

Through a dual-channel control architecture, the machine allows simultaneous machining on the main spindle and sub-spindle, dramatically improving overall cycle time and reducing idle intervals. Drilling, tapping, turning, grooving, milling, end-face machining, and cross-axis operations can be completed in a single clamping, ensuring perfect concentricity and reducing secondary processes.

The tool system is designed with productivity and flexibility in mind. Both D126 and D206 come equipped with 8 pcs 12×12 mm turning tools, 4 ER16 side live tools, a powerful 5500 r/min live tool speed, as well as multiple ER16 fixed and live tools at the spindle end and sub-spindle side. These configurations give manufacturers the capability to machine complex geometries, high-precision micro features, and multi-process compound components on one platform.

With compact machine dimensions, high-rigidity construction, premium spindle performance, and advanced multi-axis capability, the D126 and D206 Electric Spindle Swiss Lathes offer a world-class solution for precision component manufacturers looking for speed, accuracy, reliability, and true high-end machining performance.

Reviews

There are no reviews yet.