max-machining-diameter-o7-5-axis-swiss-lathe-d075a

The D075A High-Precision CNC Swiss Type Automatic Lathe is a next-generation, temperature-compensated, dual-spindle, multi-axis machining solution designed for ultra-efficient, high-accuracy production of precision components. Engineered with advanced synchronous spindle technology, high-rigidity driven tools, and an integrated one-piece mechanical structure, the D075A delivers exceptional performance, stability, and processing efficiency comparable to top-tier Japanese and European machine tool brands.

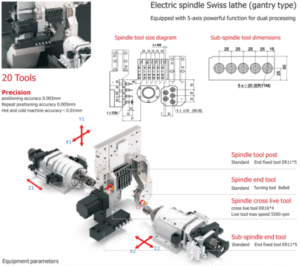

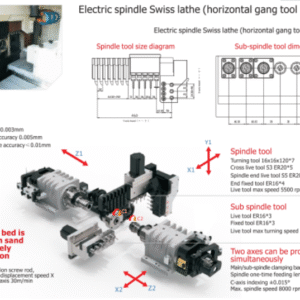

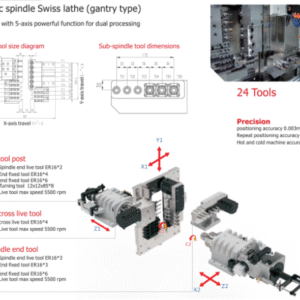

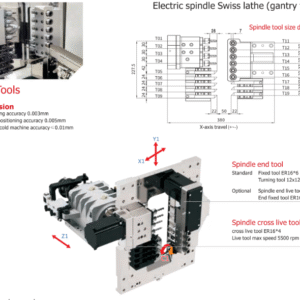

At the core of the D075A is an independently developed high-power synchronous electric spindle system, providing consistent power output to both the main spindle and sub-spindle. Each spindle features 5.5 kW of power and reaches up to 14,500 r/min, guaranteeing rapid acceleration, fast deceleration, and exceptional machining responsiveness. This ensures superior performance during high-speed turning, drilling, and tapping operations, enabling enhanced productivity and smoother machining of small-diameter bar materials ranging from φ1 mm to φ7 mm.

The D075A also incorporates a temperature-compensated control mechanism, which continuously monitors and corrects thermal variations during machining. This results in greater dimensional accuracy, reduced thermal drift, and consistently stable machining results—even during long continuous production cycles.

For tool performance, the machine features an independently developed driven-tool system, delivering low noise, strong structural rigidity, and excellent precision. The tool system supports multiple simultaneous operations, enabling complex part geometry with fewer setups. The quality and stability of driven-tool machining is on par with leading international brands, making the D075A a standout performer for precision manufacturers.

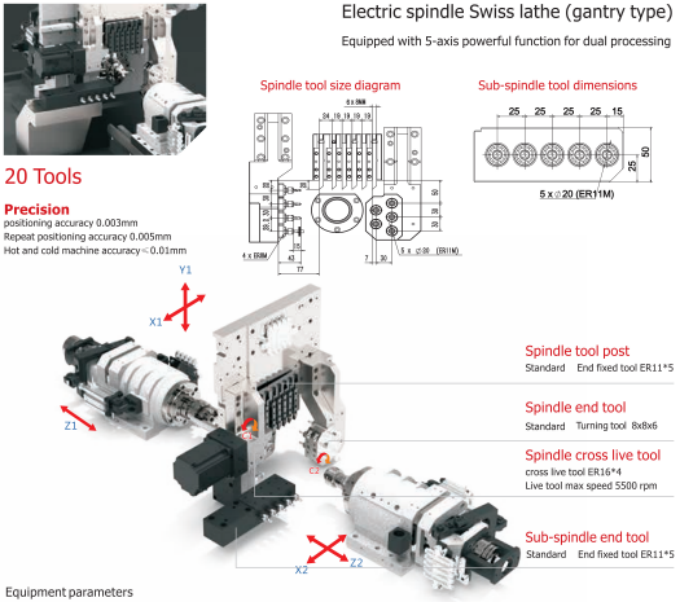

The dual-channel control architecture enables the main spindle and sub-spindle to perform separate processes simultaneously. This parallel processing capability shortens cycle times, increases production efficiency, and allows smooth part transfer between spindles. Along with full 5-axis machining capability, the D075A supports complex multi-surface machining, contouring, drilling, tapping, thread cutting, and synchronized operations.

Supporting its dynamic performance is a robust linear motion platform powered by high-power X/Y/Z axis servo motors (1200W / 750W) with large inertia capability. Combined with 20 mm guide rails, 10 mm-pitch precision ball screws, and a carriage travel speed of up to 30 m/min, the machine ensures fast, stable, and accurate movements essential for high-speed machining.

The mechanical base and structural components—machine bed, motor frame, bearing seat, and sub-spindle carriage—are all manufactured using a one-piece integrated casting. This design increases stiffness, reduces vibration, and enhances cutting stability, while also providing a more compact footprint and high-end aesthetic appearance. The D075A boasts a smooth, streamlined exterior, precise craftsmanship, and excellent ergonomic operation, reinforcing its identity as a premium machine tool.

To maximize operator convenience and production compatibility, the D075A supports both FANUC and SYNTEC control systems. These industry-standard controllers provide high reliability, mature tool-path algorithms, intuitive programming environments, and comprehensive diagnostic features.

The machine’s tooling configuration includes 6 turning tools (8×8 mm), 4 side live tools (ER11), 5 spindle-end ER11 tools, and 5 sub-spindle end ER11 tools. Live tooling speed reaches 5000 r/min, supporting powerful drilling and tapping functions on all axes.

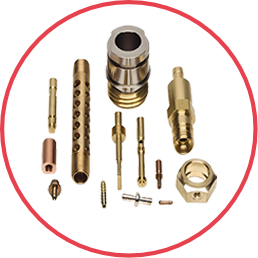

Compact yet exceptionally powerful, the D075A is engineered for industries requiring small, high-precision, high-consistency parts, such as electronics, automotive connectors, aerospace miniature components, medical equipment, instrumentation, watchmaking, and more. With its advanced technology, superior processing efficiency, and durability, the D075A is ideal for manufacturers seeking to elevate production quality while minimizing cycle times and achieving long-term operational stability.

Reviews

There are no reviews yet.