mjs500mjs1000mjs1500-dual-spindle-turning-milling-center

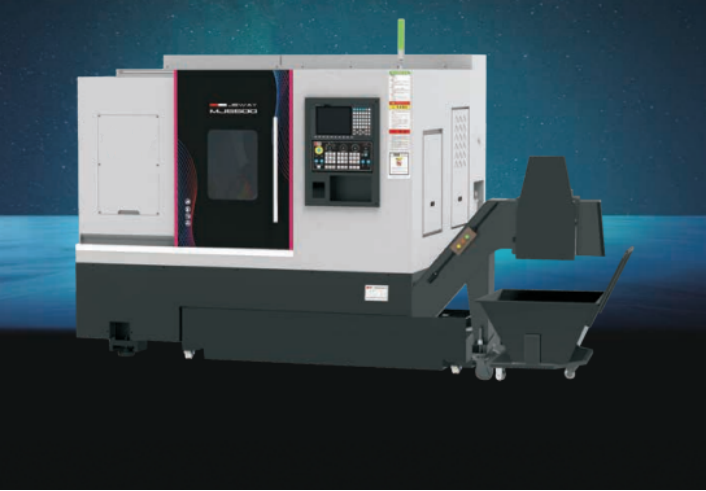

MJS500 / MJS1000 / MJS1500 Dual-Spindle Single-Turret CNC Turning & Milling Center

The MJS series represents a new generation of high-rigidity, high-precision dual-spindle CNC turning and milling centers designed for complex machining in a single setup. With its dual-spindle architecture, powerful Y-axis power turret, high-precision electric spindles, and a rigid slant-bed structure inspired by Japanese Mazak and Okuma designs, the MJS series delivers outstanding accuracy, productivity, and stability for modern manufacturing environments.

Engineered for precision parts, high-mix machining, and reduced cycle time, the MJS500, MJS1000, and MJS1500 models meet the machining demands of industries such as automotive, aerospace, hardware molds, energy equipment, and high-value custom components.

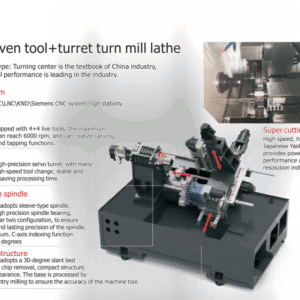

Dual-Spindle, Single Power Turret – Complete Turning & Milling in One Setup

The machine adopts a dual-spindle + single Y-axis power turret structure, allowing full turning, milling, drilling, tapping, grooving, engraving, and contour machining in the same clamping. This eliminates fixture changes and reduces positioning errors, significantly improving production efficiency.

The Jsway-customized or optional German Sauter BMT55 servo power turret includes:

-

12 fully driven stations

-

Capable of mounting 90° or 0° live tools on all stations

-

High iron-cutting power and strong rigidity

-

Tool change repeatability of 0.003mm

This advanced turret provides high torque for heavy milling, excellent rigidity for complex contours, and reliable accuracy for long-term production.

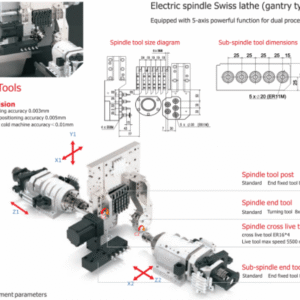

High-Precision Dual Electric Spindles

Main Spindle

The main spindle adopts:

-

A2-6 spindle interface

-

SYNTEC 18.5 kW or FANUC 22 kW built-in electric spindle

The electric spindle design ensures extremely fast response, reduced vibration, lower thermal deformation, and stable accuracy at high speeds. The spindle runout is controlled to <2 μm, meeting high-precision and high-surface-quality requirements.

Sub-Spindle

The sub-spindle features:

-

A2-5 or A2-6 spindle nose

-

11 kW or 18.5/22 kW built-in motor depending on model

The sub-spindle performs synchronous part pick-off, secondary turning, and full back-side machining without manual intervention—ideal for automation and mass production. Both spindles can operate independently and simultaneously via dual-channel control, reducing overall cycle time.

High-Rigidity Y-Axis for Complex Milling

The machine uses a highly rigid interpolation Y-axis structure. This design maintains the turret’s center of gravity within the bed’s guideway range at all times, ensuring excellent cutting stability. With a large Y-axis stroke of ±50mm, the MJS series can easily handle off-center milling, engraving, pocketing, keyways, complex contours, and oversized part features—even within a compact machine footprint.

High-Precision Ball Screws, Roller Guides & Rigid Mechanical Structure

All axes (X/Y/Z) are driven by:

-

High-precision double ball screws

-

Zero-backlash structure ensuring long-term accuracy

-

40/32mm screw diameter with 12/10mm pitch

-

45/35mm heavy-duty roller guides

This configuration provides high rigidity, rapid acceleration, and smooth dynamic response. The machine achieves:

-

30 m/min rapid feed

-

0.005mm repeat positioning accuracy

The machine body, motor base, bearing housings, and X-axis slide plate are integrally connected to maximize structural rigidity and maintain alignment over years of operation.

Mazak/Okuma-Style Slant Bed with Triangular Saddle Structure

The MJS series incorporates a 30° high-rigidity cast-iron slant bed, providing:

-

Increased structural stability

-

Smooth chip removal

-

Strong vibration absorption

-

Better ergonomics and tool accessibility

The triangular wide-saddle structure allows a large rotation radius, enhancing stability during heavy cutting and improving surface finish on difficult materials.

Super Cutting Capability for Tough Materials

Equipped with:

-

High-speed, high-precision hydraulic rotary cylinders

-

Precision collet systems

-

High-rigidity power chucks

The machine significantly improves torque transmission and cutting performance, especially for tough materials such as stainless steel, alloy steel, and titanium alloys.

Technical Specifications

Models Available:

MJS500 | MJS1000 | MJS1500

| Item | MJS500 | MJS1000 | MJS1500 |

|---|---|---|---|

| Control System | SYNTEC 220TB / FANUC 0i-TF Plus | Same | Same |

| Main Spindle | A2-6 | A2-8 | A2-8 |

| Sub-Spindle | A2-5 | A2-6 | A2-6 |

| Main Bar Capacity | φ51mm | φ72mm | φ72mm |

| Sub Bar Capacity | φ45mm | φ51mm | φ51mm |

| Max Rotation Diameter | φ450mm | φ615mm | φ615mm |

| Max Processing Length | 500mm | 1000mm | 1500mm |

| Y-Axis Travel | ±50mm | ±50mm | ±50mm |

| Rapid Feed X/Z | 30m/min | 30m/min | 30m/min |

| Repeat Accuracy | 0.005mm | 0.005mm | 0.005mm |

| Main Spindle Power | 18.5 / 22 kW | 26 kW | 26 kW |

| Sub-Spindle Power | 11 kW | 18.5 / 22 kW | 18.5 / 22 kW |

| Machine Weight | 5.5T | 6.5T | 7.2T |

Reviews

There are no reviews yet.