ml1000ml1500myl1000myl1500-series-power-turret-turn-mill-lathe

ML / MYL Series High-Rigidity Power Turret Turn-Mill CNC Lathe

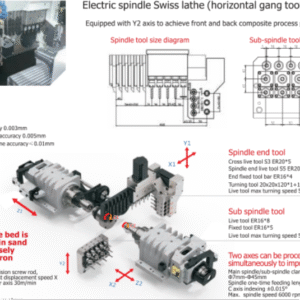

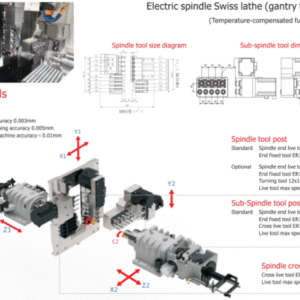

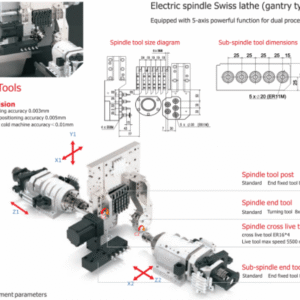

The ML1000, ML1500, MYL1000, and MYL1500 represent a new generation of high-rigidity CNC turn-mill centers designed for powerful cutting, complex machining, and high-precision production. Built with an advanced German Sauter BMT65 servo power turret, a 26 kW high-response electric spindle, a rigid 30-degree slant bed, and an integrated machine structure, this series delivers exceptional accuracy, durability, and cutting performance for demanding industrial applications.

These models are engineered for industries such as automotive components, aerospace parts, heavy equipment manufacturing, mold machining, precision hardware, and energy sector machining. They are ideal for customers who require reliable multi-process machining—including turning, milling, drilling, tapping, and engraving—in a single, stable, high-performance platform.

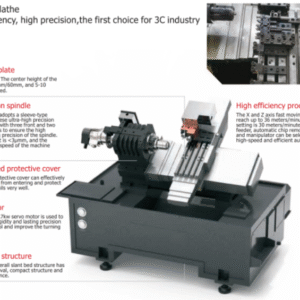

High-Power 26 kW Electric Spindle for Heavy Cutting & High Efficiency

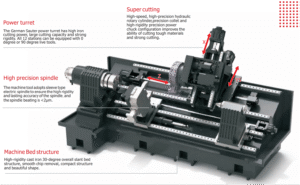

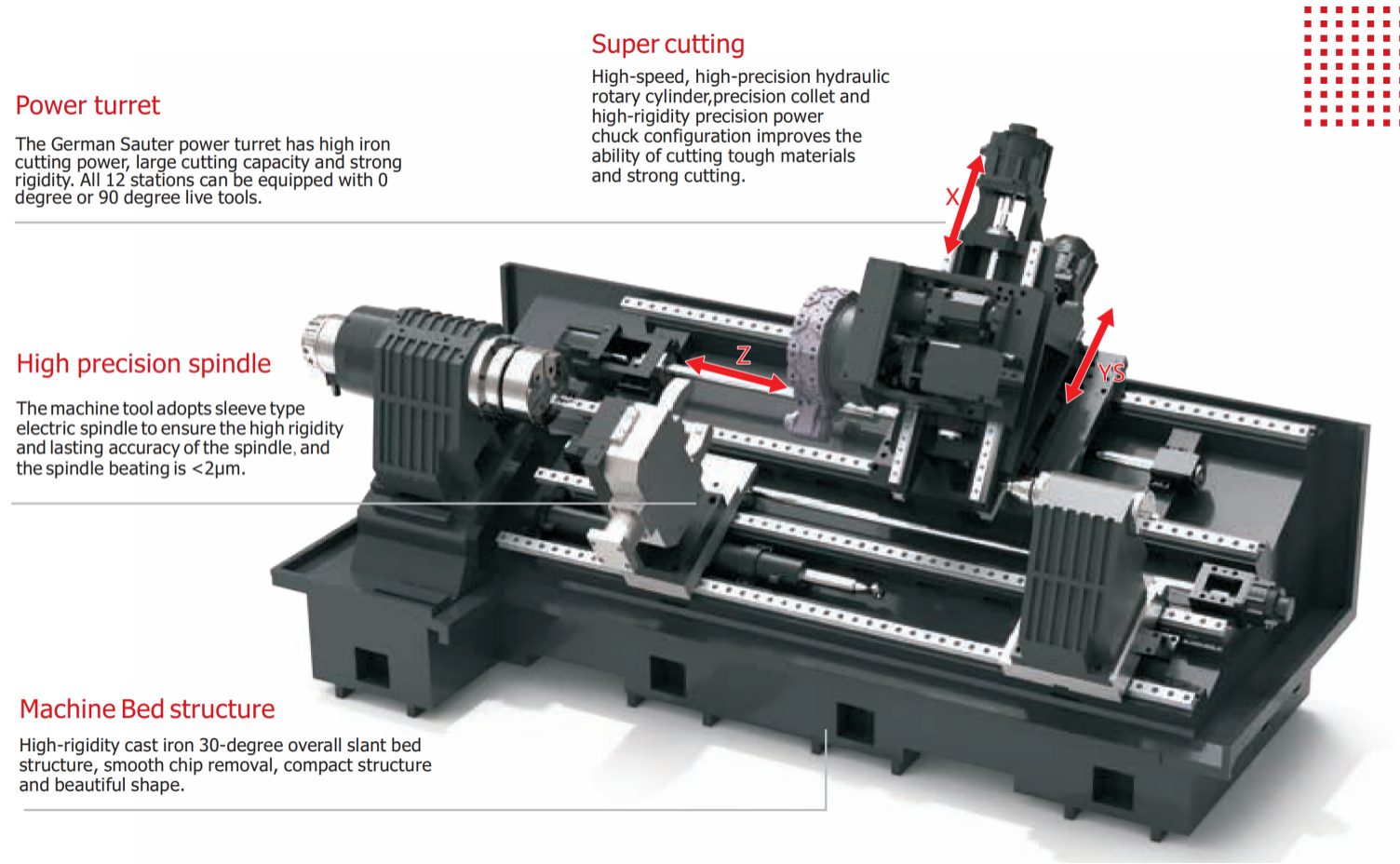

At the core of the ML/MYL series is a 26 kW sleeve-type electric spindle designed for exceptional rigidity and thermal stability. The built-in structure ensures:

-

Fast torque response for efficient metal removal

-

High rigidity for heavy-duty cutting

-

Superior surface finish quality

-

Minimized heat deformation during long machining cycles

With spindle runout controlled to <2 μm, this machine series meets the precision requirements of high-value components and difficult materials. The spindle’s large φ90 mm through-hole diameter and φ72 mm bar capacity allow stable processing of large-diameter workpieces and heavy bars.

German Sauter BMT65 12-Station Servo Power Turret

The ML and MYL series feature a BMT65 servo-driven turret with 12 stations, each capable of mounting either:

-

0° axial live tools, or

-

90° radial live tools

Key advantages include:

-

Excellent cutting rigidity

-

High torque milling capability

-

Fast, accurate tool indexing

-

Stable long-term precision

The turret’s servo tool change mechanism (1.2–1.3 kW motor) ensures rapid and repeatable indexing, supporting high-speed production environments. This turret fully enables the machine’s functionality as a complete multi-tasking CNC center capable of complex milling, drilling, tapping, and contour machining.

High-Rigidity Mechanical Structure with Integrated Components

The machine structure is engineered for stability and precision. The machine bed, motor base, bearing seat, and X-axis carriage are fully integrated, improving alignment, stiffness, and vibration control. This structure also gives the machine:

-

A compact, space-efficient layout

-

A clean, modern industrial appearance

-

Greater long-term durability under heavy cutting forces

The entire machine is built on a 30-degree high-rigidity cast iron slant bed, ensuring smooth chip evacuation, stable support for the turret and spindle, and excellent thermal absorption. The structure is designed to withstand large cutting loads while maintaining consistent machining accuracy.

High-Performance XYZ Servo Drive System

The XYZ axes are powered by high-power 2.5 kW to 3.1 kW servo motors (depending on model), providing strong thrust and reliable movement control. Each axis uses:

-

Double-nut ball screws for ultra-rigid transmission

-

Heavy-duty roller guideways (lead 32 mm, pitch 10 mm)

-

Fixed-endbearing blocks for high-precision support

These mechanical components deliver:

-

30 m/min rapid feed rate

-

Strong rigidity during heavy cutting

-

0.005 mm positioning accuracy

-

0.005 mm repeatability

The fast drag-plate movement significantly reduces non-cutting time and boosts overall productivity.

Turn-Mill Power Lathe with Tailstock (ML Series)

For long-shaft or large-diameter workpieces, the ML1000 and ML1500 include a heavy-duty hydraulic tailstock. This configuration ensures:

-

High rigidity support

-

Reduced vibration during turning

-

Improved surface finish

-

More stable machining of long parts

For customers needing additional milling capability and off-center machining, the MYL series adds a ±50 mm Y-axis, expanding its ability to perform:

-

Off-center drilling

-

Milling pockets

-

Keyway cutting

-

Helical interpolation

-

Engraving and contouring

This makes MYL models ideal for manufacturing complex parts without needing multiple machine setups.

Super Cutting Capability for Tough Materials

Equipped with high-precision components such as:

-

High-speed hydraulic rotary cylinder

-

Precision collet

-

High-rigidity power chuck

The machine maintains excellent performance in cutting hardened steel, stainless steel, alloy steel, and other tough materials. Its rigidity allows heavy-depth cutting while maintaining stable spindle load and tool life.

Processing Specs Overview

ML1000 / ML1500 (with tailstock)

-

Max processing diameter: φ650mm

-

Max processing length: 1000 / 1500mm

-

X travel: 360mm

-

Z travel: 1020 / 1520mm

MYL1000 / MYL1500 (with Y-axis)

-

Max processing diameter: φ450mm

-

Y-axis travel: ±50mm

-

X travel: 230mm

-

Z travel: 1020 / 1520mm

Shared Advantages

-

Displacement speed: 30m/min

-

Positioning accuracy: 0.005 mm

-

Repeatability: 0.005 mm

-

Machine weight: 6.5T–7.3T depending on model

Reviews

There are no reviews yet.