mx266-mx366-swiss-type-cnc-lathe

MX266 Electric Spindle Swiss Lathe – Ultimate High-Power Precision CNC mx266-mx366-swiss-type-cnc-lathe

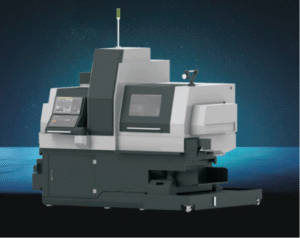

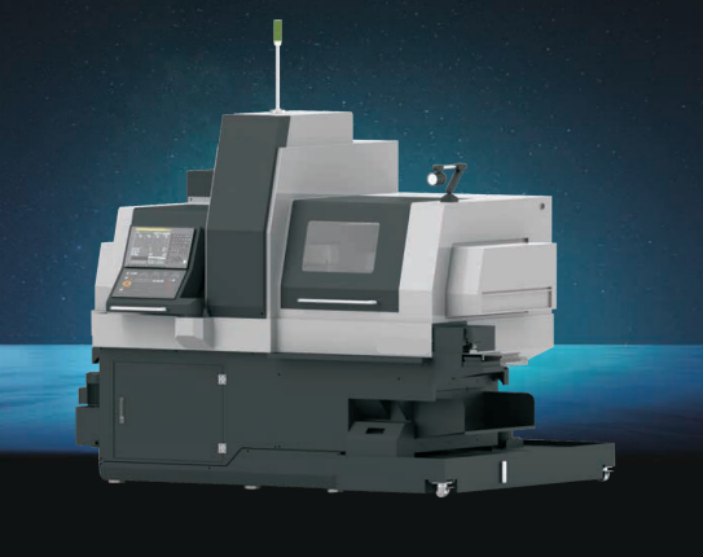

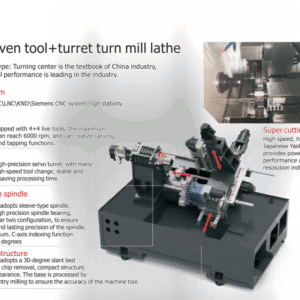

The MX266 Electric Spindle Swiss Lathe is an independently developed high-precision CNC Swiss lathe designed for high-speed, high-efficiency, and high-rigidity machining. Equipped with powerful synchronous electric spindles (FANUC 5.5KW, SYNTEC 8.2KW, optional 11KW), the MX266 Electric Spindle Swiss Lathe delivers exceptional performance in both the main spindle and the sub-spindle. From fast acceleration response to stable long-term machining performance, it provides the capabilities needed for modern precision manufacturing.

Overview of the mx266-mx366-swiss-type-cnc-lathe

The MX266 Electric Spindle Swiss Lathe is engineered for long-axis, high-speed, and high-volume precision machining. With the ability to process a 230mm long axis in a single setup, the machine significantly improves efficiency in the production of shaft-type and complex precision components. The independently developed high-power synchronous electric spindle design ensures consistent output, fast speed response, and excellent chip removal performance.

Key Features of the mx266-mx366-swiss-type-cnc-lathe

This model integrates FANUC and SYNTEC control systems to meet different automation needs. The spindle and sub-spindle share consistent torque characteristics, enabling synchronized machining and high-efficiency production. Temperature-compensation functions ensure stable accuracy even during long machining cycles.

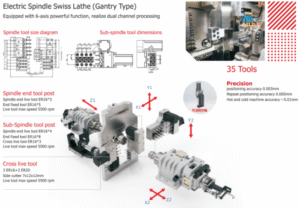

High-Power Electric Spindles

Both main and sub spindles are offered in 5.5KW, 8.2KW, or 11KW options depending on configuration. The MX266 Electric Spindle Swiss Lathe supports 6000–8000 rpm turning speeds, making it suitable for demanding industries such as automotive, aerospace connectors, medical parts, and micro-mechanical components.

Mechanical Structure of mx266-mx366-swiss-type-cnc-lathe

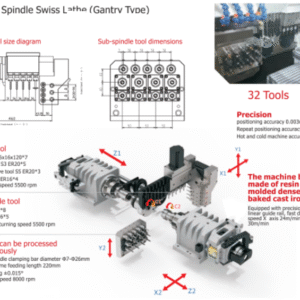

The machine adopts a large screw rod Ф32mm with a 25mm medium double-nut structure. Combined with 30mm/25mm guide rails, the MX266 Electric Spindle Swiss Lathe provides excellent rigidity and repeatable machining stability. The screw rod bearing seat is specially designed for high precision, enabling heavy cutting while maintaining superior dimensional accuracy.

The bed, motor frame, bearing seat, and sub-spindle carriage are fully connected. This ensures a compact mechanical structure with outstanding vibration absorption, thermal stability, and long-term durability. All axes use high-power servo motors (1300W and 850W thrust options) to guarantee large cutting volume with minimal vibration.

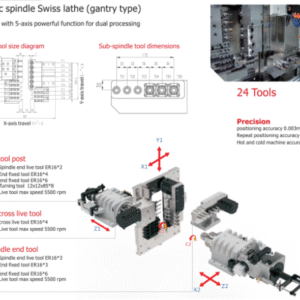

Tooling & Live Tooling – mx266-mx366-swiss-type-cnc-lathe

The MX266 Electric Spindle Swiss Lathe is equipped with 35 tool positions, making it ideal for complex multi-process machining. ER20 and ER16 driven tools support heavy cutting and stable milling operations. Four-direction driven tools (S3, S4, S5, S6) significantly expand processing flexibility.

Optional accessories include:

- Plug-in live tool system

- Whirlwind milling head

- Flying cutter head

- High-pressure coolant system (40–70kg)

These options help adapt the MX266 Electric Spindle Swiss Lathe for specialized manufacturing needs.

High-Speed Cutting Performance of mx266-mx366-swiss-type-cnc-lathe

With a 30m/min rapid travel speed, the MX266 Electric Spindle Swiss Lathe supports ultra-efficient cutting operations. High-speed dynamic performance reduces the overall production cycle while ensuring smooth chip evacuation. The fast processing mode combined with long-axis machining (230mm) allows users to machine complex parts without secondary setups.

Temperature-compensated technology ensures dimensional stability over long machining times, maintaining tolerance consistency even during high-speed operations.

Technical Specifications – mx266-mx366-swiss-type-cnc-lathe

| Model | MX266 | MX366 |

|---|---|---|

| Control System | FANUC / SYNTEC | FANUC / SYNTEC |

| Spindle Clamping Bar Dia | φ7–φ26mm | φ7–φ35mm |

| Sub-Spindle Clamping Bar Dia | φ7–φ26mm | φ7–φ35mm (guide bush φ32mm) |

| Max Drilling Diameter | φ10mm | φ10mm |

| Max Tapping Diameter | M8 | M8 |

| Cross Live Tool Drilling | φ12mm | φ12mm |

| Main/Sub Spindle Power | 5.5KW / 8.2KW | 8.2KW / 11KW |

| Max Spindle Speed | 8000 rpm | 6000 rpm |

| Movable Guide Sleeve Travel | 220mm | 220mm |

| Max Movement (No Guide Sleeve) | 360mm | 360mm |

| Tools | 35 tools | 35 tools |

| Machine Size | 2300×1890×1950 mm | 2300×1890×1950 mm |

| Weight | 3800 kg | 4000 kg |

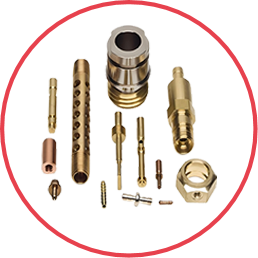

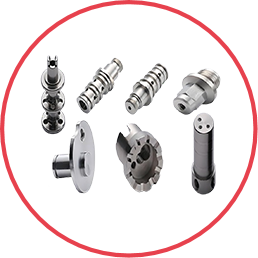

Applications of mx266-mx366-swiss-type-cnc-lathe

- Precision automotive components

- Medical device parts

- Electronic connectors

- Hydraulic and pneumatic components

- High-speed shaft and pin production

Downloads & External Resources

Download the full brochure:

MX266 Brochure (PDF)

External reference (DoFollow):

FANUC Official Website

Reviews

There are no reviews yet.