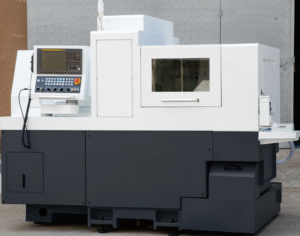

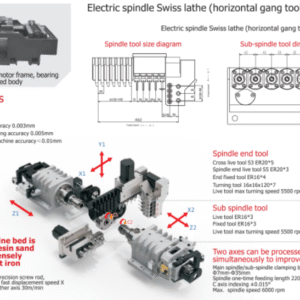

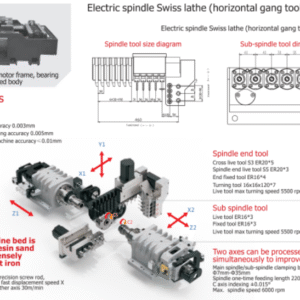

s325-sl326-sl385-s386-swiss-type-cnc-automatic-lathe-machine

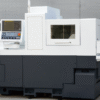

High-Precision CNC Swiss-Type Lathe – S205/S265 Series

Built for Accuracy, Efficiency, and Total Confidence in Every Cut

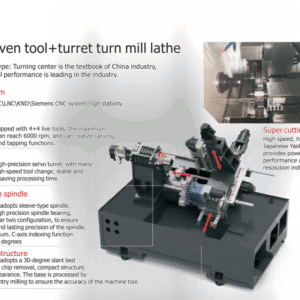

The S205/S265 Series CNC Swiss-Type Sliding Headstock Lathes are engineered for manufacturers who refuse to compromise on precision, reliability, and long-term performance. Designed for complex small-diameter machining, this machine series delivers exceptional accuracy, powerful multi-axis capability, and a rigid mechanical framework—making it the perfect solution for automotive parts, medical components, electronics, aviation hardware, and fine-mechanical industries.

Whether you are upgrading your production line, expanding capacity, or seeking a dependable solution for 24/7 high-precision machining, the S205/S265 stands as a machine you can trust.

Crafted With Premium International Components

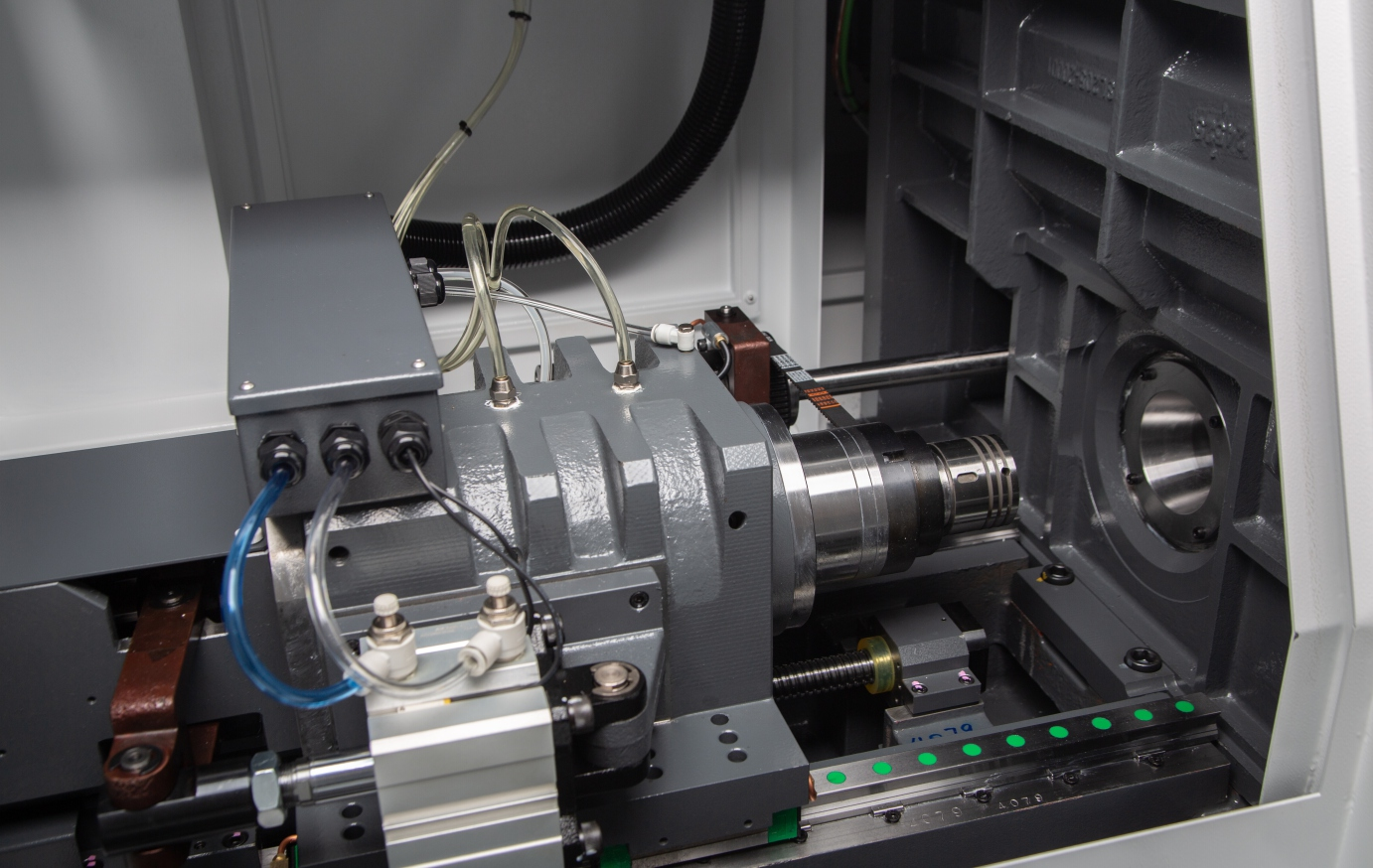

Every core component is selected to ensure durability, stability, and long machine life. The standard configuration includes a 10.4-inch dual-channel SYNTEC control system, allowing operators to program and execute complex machining operations with ease and accuracy. The system is equipped with absolute position servos, ensuring faster startup, no homing errors, and reliable positioning from the first run of the day.

Inside the machine, you’ll find world-leading brands that support consistent performance:

-

SCHNEIDER electrical components for unmatched stability

-

NSK spindle bearings (Japan) for ultra-smooth rotation

-

PM/THK imported ball screws & guideways ensuring rigidity and low friction

-

KTR shaft couplings (Germany) designed for vibration resistance

-

AIRTAC pneumatic system, OPPIN oil cooler, LANGRUI LED lighting, and OUDEN alarm lights for an optimized operating environment

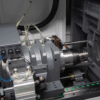

Each machine comes with a self-manufactured electric spindle, locking devices, guide bushing systems, and radial live tools—components designed and refined by our engineering team to meet high-precision manufacturing demands.

For users who prefer flexibility, the machine supports both guide bush and guide bushless configurations, allowing you to switch depending on material type, machining length, and production needs.

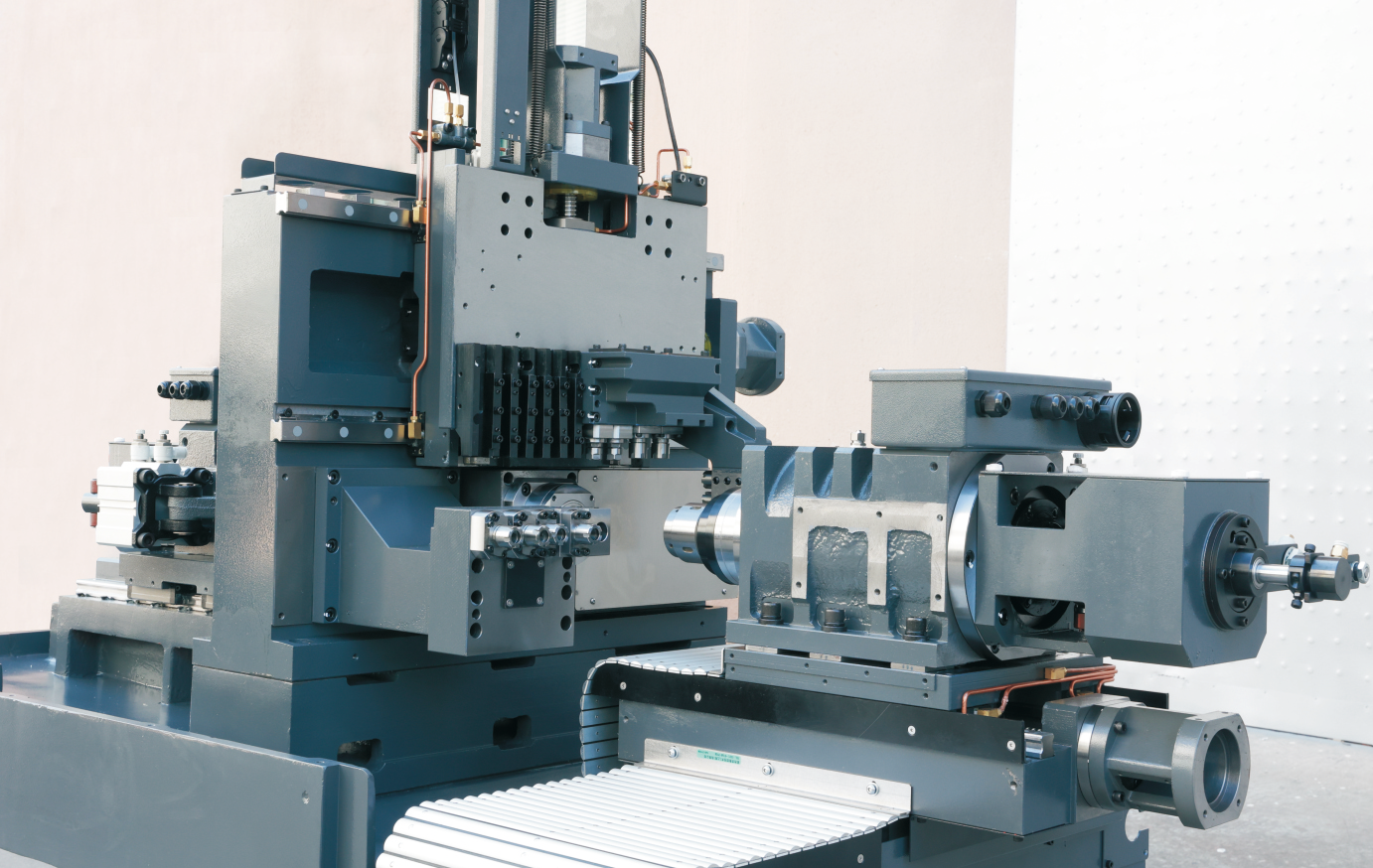

Exceptional Machining Capability That Accelerates Productivity

The S205 and S265 offer impressive processing capacity with maximum machinable bar diameters of 20 mm and 26 mm respectively. With both rotary and fixed guide-bush options, the machine is tailored for various part lengths and material requirements.

The main spindle and back spindle both deliver up to 10,000 rpm, ensuring superior surface finish and short cycle times. Live tooling—both radial and back—enables efficient drilling, tapping, milling, and cross-machining, reducing secondary operations and improving overall workflow.

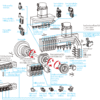

Key performance capabilities include:

-

Main spindle drilling: up to Φ10

-

Main spindle tapping: M10

-

Back spindle tapping: M10

-

Radial live tool drilling: Φ8

-

Radial live tool tapping: M6

-

Back live tool drilling & tapping: up to Φ8 / M6

High-speed live tools (6,000 rpm), a powerful 4.2 kW main spindle motor, and fully synchronized dual-side machining give the machine exceptional flexibility for producing complex parts in one setup.

Optimized Mechanical Design for High-Accuracy Production

Fast, stable, and durable—the S205/S265 is built with precision in mind. The machine offers:

-

Rapid traverse speed of up to 24 m/min

-

Main spindle runout ≤ 0.002 mm

-

Repeat positioning accuracy ≤ 0.003 mm

These specifications ensure consistent tolerance control, making the machine ideal for mass production of high-precision components.

Despite its powerful features, the machine maintains a compact footprint at 2565 × 1350 × 1850 mm, making it easy to integrate into existing production floors.

Designed for Operators, Built for Long-Term Reliability

The fully enclosed guarding improves safety, reduces noise, and keeps chips contained, ensuring a clean and efficient workspace. LED lighting provides bright visibility, while the intuitive control layout helps operators work efficiently even with complex programs.

Each machine ships with random tooling, foot spacers, and high-quality self-manufactured accessories—everything you need to start production immediately.

A Machine That Grows With You

The S205/S265 series supports OEM and customizable configurations, making it ideal for factories seeking tailored automation, tooling setups, or integration into existing production lines. It’s a system that adapts to your needs and empowers your manufacturing goals.

Reviews

There are no reviews yet.