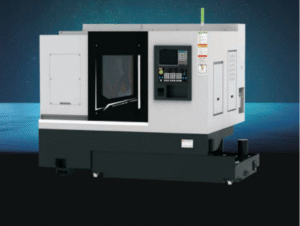

servo-turret-cnc-lathe-c400-c600-series

Servo Turret CNC Lathe (Star Model, With Tailstock)

The servo turret CNC lathe (star model, with tailstock) is designed for manufacturers who demand high rigidity, strong cutting capability, and long-term machining accuracy. Built on a compact yet powerful platform, this machine delivers exceptional performance for complex disc components, long shaft parts, and high-strength materials. Its combination of a precision servo turret, high-rigidity slant bed, and customized high-accuracy spindle makes it ideal for demanding industrial applications, from automotive to electronics and general machining workshops.

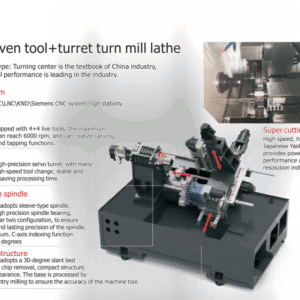

High Cutting Capacity & Strong Structural Rigidity

At the heart of the machine is a 12-station servo turret, engineered with strong rigidity and large cutting capacity. The turret can accommodate turning tools, boring tools, drilling tools, or combined tooling, enabling multi-step machining processes to be completed in one setup. This greatly increases efficiency while ensuring precise alignment and repeatability. The powerful turret design is especially suited for heavy cutting and long working hours, making the machine ideal for high-productivity environments.

The 30-degree high-rigidity cast iron slant bed further enhances stability. Manufactured as an integral structure, the bed offers excellent support against cutting vibrations and ensures consistent geometric accuracy. The slant-bed design also provides smooth chip removal, maintaining clean operating conditions and preventing chip accumulation around the tool or workpiece. This improves machining safety, reduces thermal buildup, and extends the lifespan of critical machine components.

High-Precision Sleeve-Type Spindle (<2 µm Runout)

The machine adopts a JSWAY customized sleeve-type spindle, specifically engineered for high rigidity and long-lasting precision. The spindle runout is maintained at less than 2 micrometers, making it suitable for precision turning, mirror-surface finishing, and tight-tolerance work. This level of precision ensures high repeatability from the first piece to large-volume batch production.

To support heavy-duty and high-speed cutting, the spindle is paired with a high-speed, high-precision hydraulic rotary cylinder, a precision collet, and a high-rigidity power chuck. Together, these components dramatically increase the machine’s ability to handle tough materials, high torque cutting, and continuous operation.

Program-Controlled Hydraulic Tailstock

For machining long shaft components, the machine is equipped with a program-controlled hydraulic tailstock. This intelligent tailstock automatically adjusts clamping force and position according to machining requirements, ensuring excellent support for long workpieces. It significantly improves:

-

Machining accuracy of shaft parts

-

Stability during deep-cut or long-duration operations

-

Overall process efficiency by reducing manual adjustments

By minimizing vibration and deflection, the tailstock helps achieve smoother surfaces and tighter dimensional tolerance.

Compact Size, High Efficiency, and Automation Ready

Although built for power, the machine maintains a compact footprint, making it suitable for workshops with limited space. The structure is carefully engineered to maximize rigidity while minimizing machine size, allowing factories to deploy multiple units for flexible production lines.

The machine also supports robot integration, enabling automatic loading and unloading. When combined with a robotic arm, the entire production line—material feeding, machining, and unloading—can be completed with minimal human intervention. This greatly enhances productivity, reduces labor cost, and allows the machine to operate continuously, even during night shifts.

Versatile Machining Capabilities

Thanks to its high rigidity, precision spindle, and servo turret, the machine can complete complex disc parts and long shaft parts in a single setup. This capability is extremely valuable in industries that require consistent machining quality, reduced cycle time, and minimal secondary processing.

The machine is engineered to handle a wide range of workpiece shapes and materials, making it suitable for:

-

Automotive parts

-

Aerospace connectors

-

Electronic housings

-

Machinery spindles

-

General steel components

-

Tough alloys and engineering plastics

This adaptability ensures long-term production flexibility and strong return on investment.

Super Cutting Performance

With its high-rigidity hydraulic rotary cylinder and precision chuck, the machine is built for super cutting capability. Users can confidently perform roughing, semi-finishing, and finishing operations on demanding materials. The coordinated performance of the spindle, servo turret, and bed structure maintains stability even under heavy chip loads.

Technical Specification Overview (C400A / C400B / C600A / C600B)

-

Control System: HNC or SYNTEC 22TA

-

Spindle Interface: A2-5 or A2-6 (depending on model)

-

Max Bar Diameter: φ45 mm or φ51 mm

-

Max Processing Diameter: φ400 mm

-

Max Processing Length: 400 mm (C400 series) / 600 mm (C600 series)

-

Axis Speed: X/Z up to 30 m/min

-

Repeat Positioning Accuracy: 0.005 mm

-

Turret: 12-station servo turret

-

Tailstock: Mohs 5# center

-

Spindle Motor Power: 11 kW or 18.5 kW

-

Machine Size: 2460–2780 mm length depending on model

-

Machine Weight: 3.8–4.1 tons

Conclusion

The servo turret CNC lathe (star model with tailstock) combines powerful cutting ability, long-lasting rigidity, and precision performance into a compact, automation-ready platform. Featuring a high-accuracy <2 µm spindle, 12-station servo turret, and robust slant-bed structure, it is ideal for both heavy-duty cutting and high-precision finishing. Whether producing complex disc components or long shaft parts, this machine offers stability, efficiency, and long-term reliability needed for modern industrial manufacturing.

Reviews

There are no reviews yet.