servo-turret-cnc-lathe-cfg46d-cfg56d-m46d-m56d

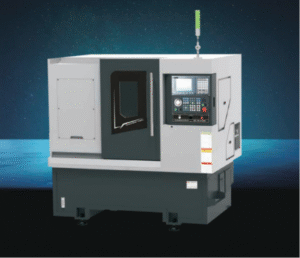

CFG46D / CFG56D / M46D / M56D Servo Turret CNC Lathe Series

The CFG46D, CFG56D, M46D, and M56D series represent a new generation of high-efficiency, high-rigidity servo turret CNC lathes designed for precision machining of small and medium-sized disc parts and short shaft components. Engineered with advanced spindle technology, fast servo axes, and an ultra-rigid structural design, this series offers exceptional reliability, long-lasting accuracy, and superior surface finish—even under heavy uninterrupted production.

High-Efficiency Machining Powered by Advanced Axis System

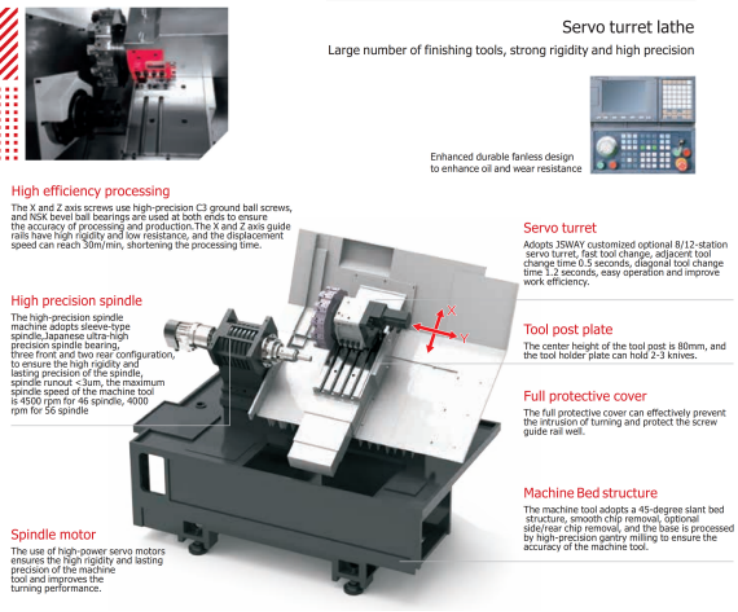

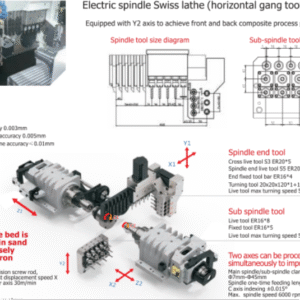

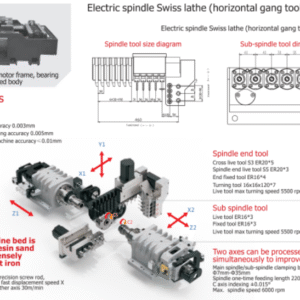

The machine is equipped with high-precision C3 ground ball screws on both X and Z axes. These screws are paired with NSK matched-angle ball bearings at both ends, minimizing thermal deformation and ensuring stable accuracy during long production cycles. Combined with rigid linear guideways, the motion system delivers extremely low friction and stable high-speed displacement.

The rapid traverse speed of the X and Z axes can reach 30 m/min, significantly shortening machining cycles and improving throughput for mass-production environments.

The Z-axis features a 40 mm large-diameter screw, providing stronger thrust, higher load capacity, and smoother acceleration during long-travel operations. This design is critical for improving stability when cutting tough materials or performing high-speed turning routines.

High-Precision Spindle System for Demanding Applications

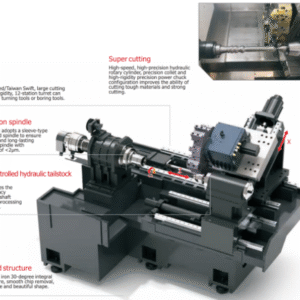

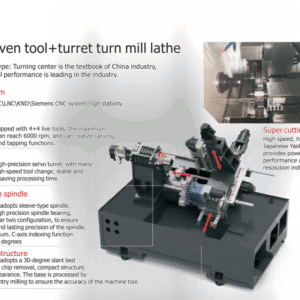

At the core of the machine is a high-performance sleeve-type spindle with an ultra-rigid Japanese bearing configuration—three bearings in the front and two in the rear. This structure ensures high rigidity, excellent heat dissipation, and outstanding long-term precision retention.

The spindle achieves exceptionally low runout of <3 μm, delivering high surface quality and excellent roundness performance.

Two spindle configurations are available to suit different machining needs:

-

46 spindle: Maximum speed 4500 rpm

-

56 spindle: Maximum speed 4000 rpm

These spindle options make the machine suitable for high-speed finishing cuts, high-gloss machining, and precise dimensional control. Thermal stability is another highlight—both cold and hot machine dimensions remain nearly unchanged, ensuring consistent machining accuracy during extended operation.

High-Power Servo Motor for Stable Cutting

The machine uses a high-torque servo spindle motor that provides powerful acceleration and constant torque output across a wide speed range. This enhances cutting performance, stability, and chip control when cutting stainless steel, alloy steel, or other tough materials.

The use of servo motors also improves low-speed accuracy, making the machine well-suited for threading, grooving, and fine finishing operations.

Servo Turret – High Speed, High Rigidity, High Reliability

The lathe features a JSWAY-customized servo turret with optional 8-station or 12-station configurations.

This turret is engineered for rapid and precise tool changes, enabling:

-

Adjacent tool change time: 0.5 seconds

-

Diagonal tool change time: 1.2 seconds

-

High socket rigidity for stability under heavy cutting loads

The turret’s strong clamping force and high repeat accuracy allow uninterrupted machining of multiple processes in a single setup, improving overall productivity.

The tool post has a center height of 80 mm and supports 2–3 tools, providing greater flexibility for special operations and multi-functional tool layouts.

Robust Machine Structure and Excellent Thermal Stability

The machine uses a 45-degree high-rigidity slant-bed structure that ensures smooth chip evacuation, stable support for heavy cutting, and superior accessibility for operators.

The base is machined using a high-precision gantry milling center, ensuring tight geometric tolerances throughout the machine frame.

Users may choose between:

-

Standard casting base

-

Heavy-duty casting base (CZG46D / CZG56D)

Both options deliver excellent vibration absorption while the enhanced version offers even greater rigidity for demanding production lines and tougher materials.

A full protective enclosure shields the guideways and screws from chips and coolant, extending machine life and improving workplace safety.

Enhanced Durability and Improved User Experience

The machine incorporates a robust fanless design that enhances oil resistance and wear resistance, providing longer mechanical life and reduced maintenance.

With the combination of powerful servo systems, high-speed spindle capability, and a rigid structural base, the machine series is engineered to operate continuously under industrial mass-production conditions.

Flexible Configuration Options

The series supports a wide range of applications thanks to the flexible spindle and turret options:

-

46 spindle or 56 spindle (A2-5 / A2-6)

-

8+3 tool layout

-

Optional side or rear chip removal

-

Multiple turret specifications for various part families

These configuration options allow users to tailor the machine to their exact production requirements, whether for automotive parts, hardware products, instrumentation components, or precision industrial fittings.

A Complete and Reliable High-Precision Turning Solution

Combining advanced servo technology, heavy-duty mechanical structure, and long-lasting accuracy, the CFG46D/CFG56D/M46D/M56D series stands as a powerful modern CNC turning center.

It is engineered for customers who demand:

-

High precision

-

High speed

-

Long-term stability

-

Efficient cycle times

-

Flexible tool configurations

-

Superior surface finish

This series offers exceptional value and performance, making it ideal for competitive manufacturing industries requiring stable, high-volume production with strict tolerance requirements.

Reviews

There are no reviews yet.