single-spindle-y-axis-power-turret-turn-mill-lathe-msy300msy300fmsy500msy500f

The MSY-Series single-spindle power turret turning–milling center is engineered to deliver high-efficiency machining, superior rigidity, and stable precision for complex part production. It integrates a high-performance power turret, Y-axis interpolation capability, a rigid slant-bed foundation, and optional robotic automation to create a highly productive multitasking CNC platform suitable for both disc-type and long-shaft components. This series is designed to meet advanced machining needs in industries such as automotive, precision hardware, energy equipment, pneumatic components, and instrumentation.

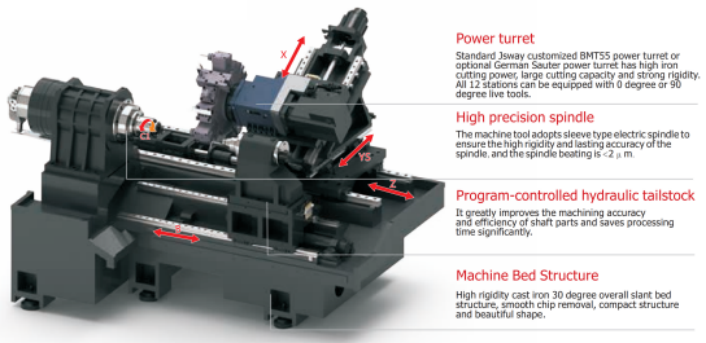

High-Performance Power Turret for Heavy Cutting

The machine is equipped with a standard BMT55 power turret, or an optional German Sauter servo power turret, both known for their exceptional cutting rigidity and durability under heavy load. All twelve stations on the turret support 0° or 90° live tooling, enabling a broad range of machining operations including side milling, drilling, tapping, and contour machining. The turret is engineered to maintain high torque transmission and stable tool indexing under strong cutting conditions, making it suitable for steel, stainless steel, alloy steel, and high-hardness materials.

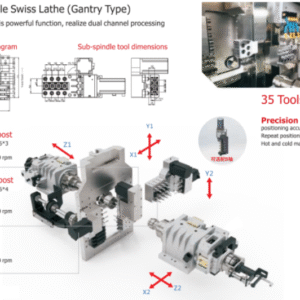

Y-Axis Turning–Milling Function for One-Stop Machining

The MSY-Series features a 30-degree composite Y-axis structure, which keeps the turret’s center of gravity inside the saddle guide rails at all times, significantly improving the machine’s rigidity during milling operations. With ±50mm of Y-axis travel, the machine supports full turning–milling composite machining, allowing the user to finish multiple processes—including milling, carving, drilling, grooving, and tapping—in a single setup. This dramatically improves overall cycle time, reduces accumulated tolerance errors, and increases production throughput.

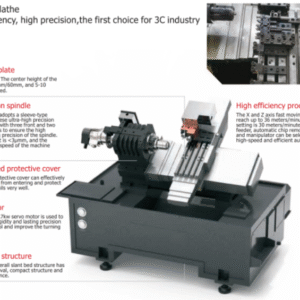

Rigid 30° Slant Bed Based on Japanese Mazak/Okuma Structure

Inspired by the structural design principles of Japanese Mazak and Okuma machines, the MSY-Series adopts a high-rigidity 30-degree integral slant bed made of high-strength cast iron. This triangular saddle foundation provides exceptional stability and vibration absorption, ensuring excellent surface finishes and prolonged tool life. The open slant-bed design promotes smooth chip evacuation, even during continuous heavy-duty cutting, while maintaining a compact and visually refined machine layout.

High-Precision Sleeve-Type Electric Spindle

To guarantee long-term geometric accuracy, the machine uses a sleeve-type electric spindle with <2μm runout. This construction increases bending stiffness and thermal stability, preventing deformation during long machining cycles. The spindle system incorporates a magnetic ring encoder, supporting interpolation, contour machining, and dividing accuracy up to ±0.015°. Powerful spindle options—A2-5 or A2-6, with motor power configurations ranging from 11KW to 22KW—enable high torque and smooth operation across a wide range of materials.

The spindle speed reaches 4500 r/min for A2-5 models and 4000 r/min for A2-6 models, meeting the performance needs of both precision micro-cutting and robust material removal.

Automation Ready with Robotic Loading

The MSY-Series is designed for intelligent production lines. Users can install a robot arm for fully automated loading and unloading of parts. Such automation increases production consistency, reduces labor costs, and supports 24/7 unmanned operation—ideal for medium- to large-scale production environments.

Program-Controlled Hydraulic Tailstock for Shaft Parts

A program-controlled hydraulic tailstock greatly enhances the stability and precision of long-shaft machining. It ensures rigid support during rough turning and finishing, reduces vibration, and significantly improves dimensional accuracy. This feature also shortens cycle times and contributes to stable mass-production performance.

High-Speed, High-Rigidity Cutting Capability

The machine is built for super cutting performance. Key components—including the hydraulic rotary cylinder, precision collet, and high-rigidity power chuck—are carefully matched to improve performance when cutting tough and high-strength materials. The strong clamping capability ensures smooth, reliable operation even under demanding cutting loads.

Servo System and Rapid Axis Motion

The MSY-Series uses a high-performance servo system to achieve rapid axis motion, excellent accuracy, and reliable dynamic response.

-

X/Z axis rapid traverse: 30 m/min

-

Positioning accuracy: 0.005mm

-

Repeatability: 0.005mm

These specifications ensure excellent machining detail and short tool-to-tool positioning time.

Servo motor power configurations vary by model:

-

2.4KW or 1.8KW servo motors for X and Z axes

-

2.4KW or 1.8KW servo motors for the Y axis

The combination provides a balanced solution for high-speed motion and strong cutting load resistance.

Multifunctional Turning–Milling Platform

Whether configured as a single-spindle power turret lathe or a single-spindle Y-axis turning–milling center, the MSY platform can perform a full suite of machining processes in a single setup:

-

Turning

-

Milling

-

Drilling

-

Slotting

-

Tapping

-

Engraving

-

Circular interpolation

-

Composite contouring

This allows manufacturers to replace multiple machines with one intelligent machining center, reducing floor space and cost while increasing productivity and precision.

Compact Footprint with Strong Performance

Despite its powerful configuration, the MSY-Series maintains a compact footprint, enabling installation in small-to-medium factory spaces:

-

MSY300 Series: 2240 × 1950 × 1950mm

-

MSY500 Series: 3122 × 2100 × 1920mm

Machine weight ranges from 4.5T to 5T, ensuring adequate mass for vibration control and structural stability.

Reviews

There are no reviews yet.