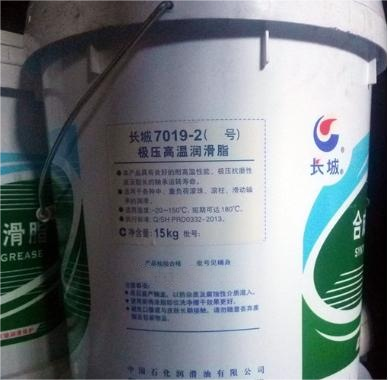

sinopec-7019-2-extreme-pressure-high-temperature-lubricating-grease

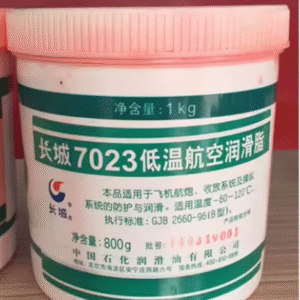

Great Wall® 7019-2 Extreme Pressure High-Temperature Grease

Reliable Lubrication for High-Load and High-Temperature Industrial Equipment

Great Wall® 7019-2 Extreme Pressure High-Temperature Grease is a high-performance industrial lubricant specifically developed for equipment operating under high temperatures and heavy loads. It is formulated with deeply refined mineral base oil thickened by a composite metal soap system and enhanced with a carefully balanced additive package including extreme pressure (EP), anti-wear, antioxidant, and rust-preventive agents. This advanced formulation provides stable lubrication performance, strong load-carrying capability, and reliable protection for bearings and friction pairs in demanding operating environments.

The product is designed to accommodate various lubrication methods. NLGI Grade 1 grease is suitable for centralized lubrication systems, while NLGI Grades 2 and 3 are ideal for manual grease application, offering flexibility to meet different equipment requirements and maintenance practices.

Product Overview

Great Wall® 7019-2 is engineered to deliver long-lasting lubrication under conditions where conventional greases may soften, flow away, or degrade rapidly. Its composite metal soap thickener provides excellent thermal stability, allowing the grease to maintain consistency and adhesion at elevated temperatures. The refined mineral oil base ensures adequate oil film strength to support heavy loads while maintaining reliable lubrication over extended service intervals.

By combining high-temperature resistance with strong extreme pressure and anti-wear properties, 7019-2 effectively reduces friction and wear, helping to protect critical components and improve overall equipment reliability.

Key Performance Features

Excellent High-Temperature Resistance

7019-2 demonstrates outstanding resistance to high operating temperatures. Even when friction points are exposed to elevated heat or high ambient temperatures, the grease resists softening and leakage. This ensures that bearings and friction surfaces receive continuous lubrication, effectively extending bearing service life under high-temperature conditions.

Strong Extreme Pressure and Anti-Wear Performance

The grease provides excellent EP and anti-wear characteristics, enabling it to withstand heavy loads and certain impact loads commonly encountered in industrial machinery. It forms a durable protective film that minimizes metal-to-metal contact, reduces surface fatigue, and prevents premature component failure.

Good Oxidation Stability

7019-2 exhibits reliable oxidation stability, preventing grease degradation during prolonged operation. This characteristic ensures a longer usable life of the lubricant, reduces the formation of harmful oxidation by-products, and supports extended relubrication intervals.

Reliable Rust and Corrosion Protection

With effective rust-preventive additives, the grease provides continuous protection for lubricated parts, shielding metal surfaces from corrosion caused by moisture, humidity, or harsh operating environments. This contributes to improved equipment durability and reduced maintenance costs.

Environmentally Responsible Formulation

The product does not contain heavy metals, nitrites, or other substances harmful to human health. Its formulation is designed to avoid introducing new environmental pollution, making it suitable for use in modern industrial operations with higher environmental and safety requirements.

Technical Standard Compliance

Great Wall® 7019-2 Extreme Pressure High-Temperature Grease complies with Q/SH PRD 332-2010, ensuring consistent product quality and performance reliability for industrial applications.

Applications

Great Wall® 7019-2 is widely used in industries where equipment operates under high temperature and medium to heavy loads. Typical application areas include:

-

Petrochemical processing equipment

-

Steel and metallurgical plants

-

Mining and mineral processing machinery

-

General mechanical equipment

-

Transportation and heavy-duty industrial systems

It is suitable for the lubrication of ball bearings, roller bearings, and sliding bearings operating under high-temperature, medium-load, and heavy-load conditions. Its balanced performance makes it an ideal choice for both continuous operation and intermittent duty equipment.

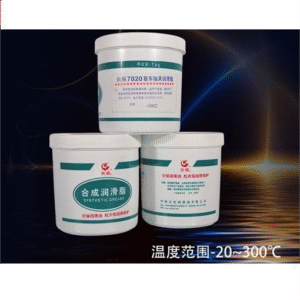

Operating temperature range:

-

-20°C to +160°C

Lubrication Methods

-

NLGI Grade 1: Recommended for centralized lubrication systems, ensuring smooth grease delivery and uniform lubrication across multiple points.

-

NLGI Grades 2 and 3: Suitable for manual grease application, providing enhanced sealing and load-bearing performance at individual lubrication points.

Storage and Handling Recommendations

To ensure optimal performance, Great Wall® 7019-2 should be stored and transported in a clean, dry environment. During storage and application, care should be taken to prevent contamination by water, dust, or other impurities. The grease should not be mixed with other lubricants, as this may adversely affect performance and service life.

Conclusion

Great Wall® 7019-2 Extreme Pressure High-Temperature Grease is a dependable lubrication solution designed for high-temperature and high-load industrial applications. With its excellent thermal resistance, strong EP and anti-wear performance, reliable oxidation stability, and effective rust protection, it provides continuous protection for bearings and friction components. Environmentally responsible and compliant with industry standards, 7019-2 helps extend equipment life, reduce maintenance frequency, and support stable, efficient industrial operations.

Reviews

There are no reviews yet.