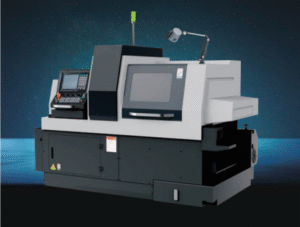

td265-swiss-type-cnc-lathe

Advanced & High-Performance TD265 Swiss Type CNC Lathe – Excellent Precision and Superior Productivity

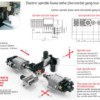

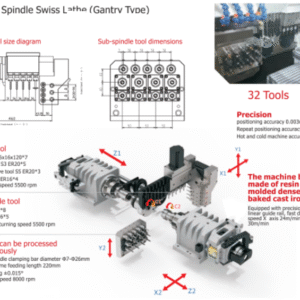

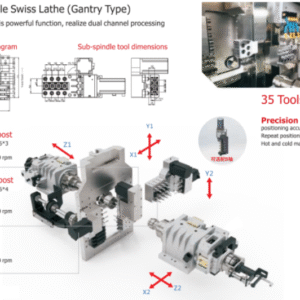

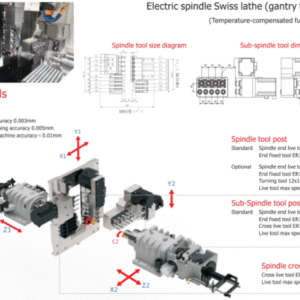

The TD265 Swiss Type CNC Lathe is an advanced, high-performance machining solution engineered to deliver remarkable precision, excellent productivity, and stable long-hour cutting capacity for demanding industrial production environments. Designed with a compact horizontal gang tool structure and powered by high-torque synchronous electric spindles, the TD265 provides the breakthrough efficiency required for mass-production of small-to-medium diameter metal components. This model integrates intelligent CNC technology, temperature-compensated accuracy control, and premium mechanical rigidity optimized for aerospace, automotive, electronics, and precision medical component processing.

Why the TD265 Swiss Type CNC Lathe is the Ultimate Choice

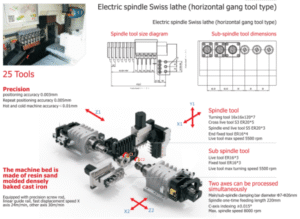

The TD265 features independently developed high-power electric spindle systems compatible with FANUC 5.5KW and SYNTEC 8.2KW, offering equal power for both main and sub-spindle configurations. With rapid speed response and strong output torque, the machine supports high-speed cutting up to 8000 rpm, ensuring excellent machining stability and superior surface finish. The electric spindle architecture provides faster acceleration, reduced cycle time, and improved spindle vibration control. These strengths enable manufacturers to significantly increase productivity and shorten production lead time.

Key Features of TD265 Swiss Type CNC Lathe

- High-speed production performance: Fast travel speed of 30m/min for reduced machining cycle time and increased efficiency.

- Long-axis machining capability: One-pass machining length of 220mm supports deep-hole drilling and extended-part processing.

- Large bar stock capability: Supports maximum material diameter φ7-φ26mm suitable for diverse industrial applications.

- High stiffness mechanical foundation: Equipped with large screw rod Ф32mm and guide rails 30mm / 25mm to maintain exceptional cutting stability even under heavy loads.

- Temperature-compensated structure: Maintains dimension accuracy during long-hour continuous production.

- High-power servo drive: Each axis uses 1300W / 850W servo motors delivering high thrust force for aggressive material removal.

- Extensive tooling compatibility: Up to 25 tool positions, driven tool ER20 / ER16, optional plug-in live tool, whirlwind tool, and flying-knife cutter capabilities.

- High live tool performance: Driven tool turning speed up to 5500 r/min, drilling capability Φ12mm and tapping capacity M8 / M10.

- High-pressure coolant: Standard 40-70kg system ensures optimal chip removal for stainless steel, titanium and high-strength alloys.

Tooling & Processing Configuration of TD265

Tool holders include 7 turning tools (16×16mm), 5 ER20 side live tools, and 4 ER16 + 3 ER20 spindle end tools with 3 ER16 + 3 ER16 live/fixed sub-spindle tools. With multi-axis live tooling support, the TD265 enables drilling, milling, slotting, grooving, tapping, and dynamic contour machining in a single machine platform. This dramatically reduces the need for secondary operations and improves repeatability and part-quality consistency.

Industry Applications of TD265 Swiss Type CNC Lathe

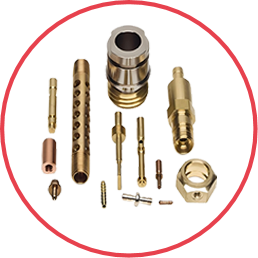

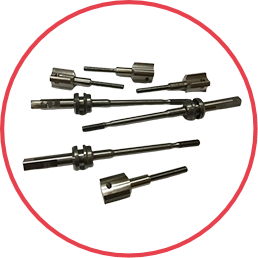

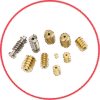

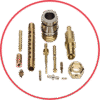

The machine is widely used for production of precision cylindrical components including:

- Medical bone screws, orthopedic implants and surgical instruments

- Electronic connectors, mobile device shafts and miniature precision hardware

- Automotive engine pins, valves, bushings, steering and transmission parts

- Aerospace fasteners and instrument components

- Timepiece mechanisms and measuring instrument parts

External & Internal Resources

Learn more about FANUC Industrial CNC Technology.

Explore our Machine Tool Lubricants Guide to enhance cutting lifespan and improve performance stability.

The TD265 Swiss Type CNC Lathe is a premium investment for manufacturers seeking superior accuracy, exceptional throughput, reduced labor dependency, and faster return on equipment value. With excellent structural design, reliable system integration, and powerful real-world machining capabilities, the TD265 stands out as one of the most competitive solutions for modern precision manufacturing.

Reviews

There are no reviews yet.