td266-electric-spindle-swiss-lathe

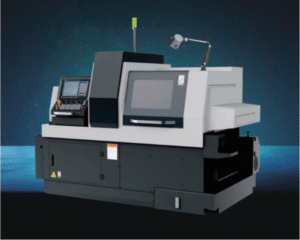

TD266 Electric Spindle Swiss Lathe — Ultimate High-Performance Gantry

TD266 Electric Spindle Swiss Lathe — Ultimate High-Performance Gantry CNC

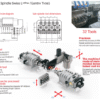

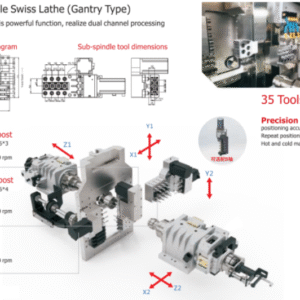

Model: TD266 Electric Spindle Swiss Lathe | Type: Gantry Type | Highlights: FANUC 5.5KW / SYNTEC 8.2KW, 8000 rpm, 32 tool stations.

Overview — td266-electric-spindle-swiss-lathe

The TD266 Electric Spindle Swiss Lathe is a gantry-type, high-speed Swiss lathe engineered for precision and throughput. Designed around independently developed high-power electric spindles, the TD266 Electric Spindle Swiss Lathe combines consistent main/sub-spindle power with rapid start/stop response for efficient, high-quality turning and milling operations. This machine supports 8000 rpm spindle speeds and offers a robust tool bank of up to 32 tools, making it ideal for complex, small-diameter parts manufactured at scale.

Key Features of the td266-electric-spindle-swiss-lathe

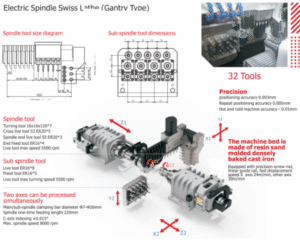

Powerful Electric Spindles

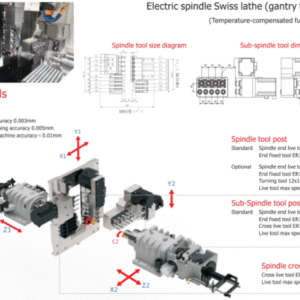

The TD266 Electric Spindle Swiss Lathe uses high-power electric spindle designs: FANUC 5.5KW or SYNTEC 8.2KW options. Main and sub spindles deliver matching power for synchronized high-efficiency operations. With a maximum spindle speed of 8000 rpm, the TD266 supports high-speed cutting and fast cycle times.

Robust Mechanical Structure

The machine bed, motor frame, bearing seats, and sub-spindle carriage are integrally connected for rigidity and thermal stability. The TD266 Electric Spindle Swiss Lathe employs a large screw rod with a double nut (32mm/φ25mm) and high-precision screw rod bearing seats to ensure repeatable accuracy under heavy cutting loads.

High Tooling Flexibility

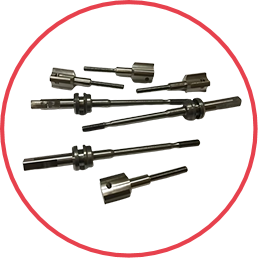

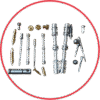

Standard configuration includes an upper single-row tool layout with 32 tools; optional plug-in driven tools and cyclone milling heads are available. Driven tool options (ER20 / ER16) provide strong milling rigidity. Multiple driven tools (S3/S4/S5) across axes simplify complex machining tasks on the TD266 Electric Spindle Swiss Lathe.

High-Speed Motion & Cooling

With a maximum running speed of 30 m/min and optional high-pressure coolant (40–70 kg), the TD266 Electric Spindle Swiss Lathe keeps chips clear and cutting temperatures low, improving tool life and surface finish.

Technical Specifications — td266-electric-spindle-swiss-lathe

| Item | Parameter |

|---|---|

| Model | TD266 |

| Control System | FANUC / SYNTEC |

| Main/Sub Spindle Power | FANUC 5.5KW / SYNTEC 8.2KW |

| Max Spindle Speed | 8000 r/min |

| Spindle Linkage Movable Guide Sleeve Travel | 220 mm |

| Max Movement (without guide sleeve) | 360 mm |

| Main/Sub Spindle Max Bar Dia | φ7–φ26 mm |

| Main/Sub Spindle End Max Drilling Dia | φ12 mm |

| Max Tapping Dia (Main/Sub) | M10 / M8 |

| Cross Live Tool Max Drilling | φ12 mm |

| Tools | 7 Turning tools 16×16 mm; Sub & Spindle tool combos: ER16/ER20 driven tools |

| Machine Size (L×W×H) | 2700 × 1450 × 1800 mm |

| Weight | 3800 kg |

Performance & Reliability — td266-electric-spindle-swiss-lathe

The TD266 Electric Spindle Swiss Lathe delivers consistent torque and stable thermal performance via temperature compensation and a compact mechanical layout. Each axis is driven by high-power servo motors (1300W / 850W thrust options) to handle large cut volumes while maintaining positional accuracy. The spindle-bearing seats and guide rails (30 / 25 mm) combine to provide excellent cutting rigidity and long-term repeatability.

Durability features include reinforced bearing seats, optimized cooling channels, and standardized modular components for easier maintenance and faster parts replacement. For high-volume production of small, complex parts, the TD266 Electric Spindle Swiss Lathe reduces cycle times and lowers per-piece costs.

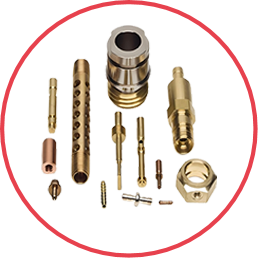

Typical Applications for the td266-electric-spindle-swiss-lathe

- Precision automotive components (fasteners, pins, small shafts)

- Medical device components requiring high surface quality

- Electronics hardware and connectors

- Hydraulic fittings and small valve bodies

- Any small-part production where repeatable precision and throughput matter

Ordering, Options & Customization — td266-electric-spindle-swiss-lathe

Optional configurations: alternative spindle power (FANUC or SYNTEC), plug-in driven tools, cyclone milling head, high-pressure coolant (40–70 kg), and extended tool banks. We can provide turnkey packages with tooling kits and recommended cutting parameters tailored to your materials and cycle-time goals.

Why choose the TD266 Electric Spindle Swiss Lathe?

The TD266 Electric Spindle Swiss Lathe blends high-speed capability with rigid construction and flexible tooling — delivering a measurable advantage in throughput for precision parts manufacturing. Its gantry design and matched main/sub spindle power make operations predictable and easy to integrate into automated production lines.

Contact & Downloads

If you would like a quotation, CAD model, or performance test report for the TD266 Electric Spindle Swiss Lathe, contact our sales team or download the full datasheet.

Download TD266 Datasheet (PDF)

External resources: Controller Manufacturer (technical reference).

Reviews

There are no reviews yet.