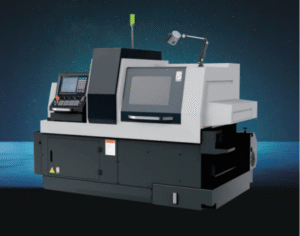

td365-swiss-type-cnc-lathe-25-tool-hydraulic-clamp-11kw

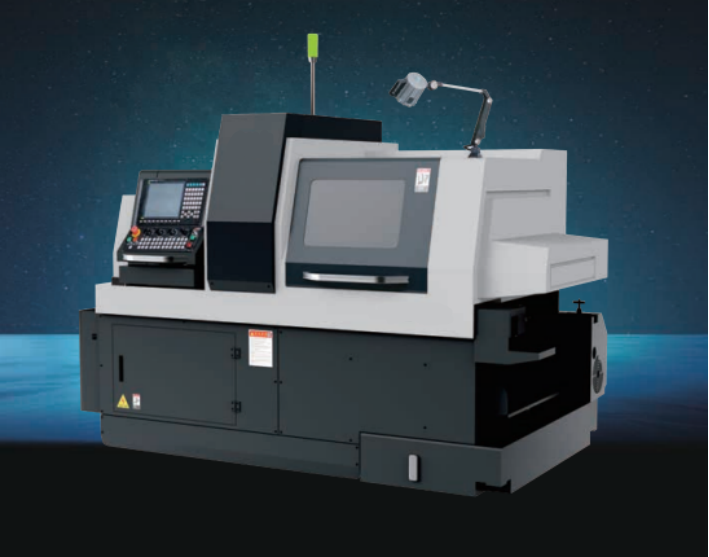

TD365 Swiss-Type CNC Lathe – High-Precision, High-Rigidity, High-Efficiency Turning Solution

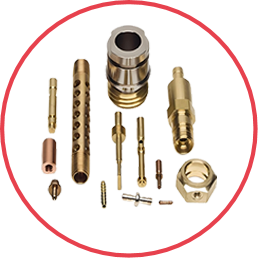

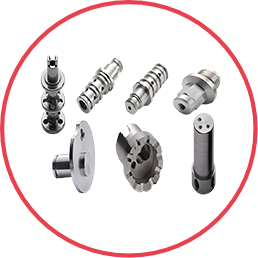

The TD365 Swiss-Type CNC Lathe is engineered for precision, rigidity, and continuous high-efficiency machining. Designed for demanding applications such as precision shaft machining, medical components, automotive parts, aerospace fittings, and electronics hardware, the TD365 delivers exceptional stability and cutting capability. Its advanced structural design, powerful drive system, and comprehensive tooling configuration make it a highly versatile production machine suitable for both medium and large-scale manufacturing.

High-Rigidity Hydraulic Clamping for Stable Machining

The TD365 adopts a main and sub-spindle hydraulic clamping structure using a hydraulic rotary cylinder. This configuration ensures firm and reliable clamping even during deep drilling or heavy cutting operations. By preventing material pullback caused by insufficient clamping force, it enhances machining precision and improves cutting consistency—critical when processing long shafts or difficult materials.

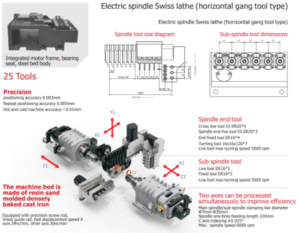

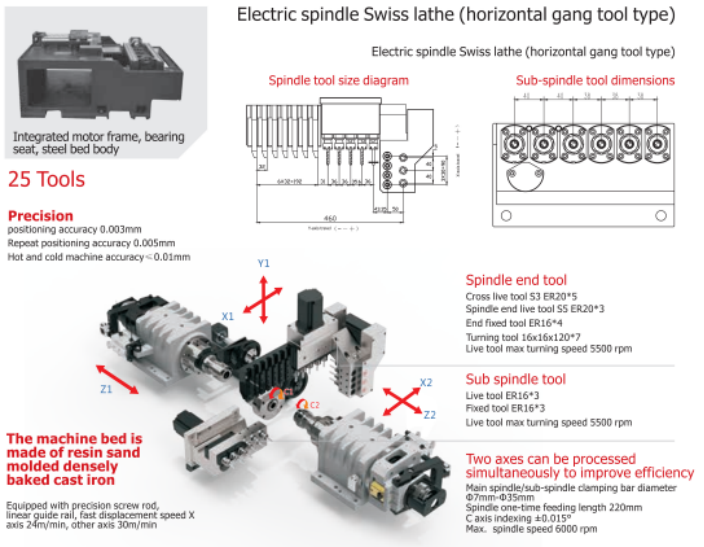

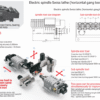

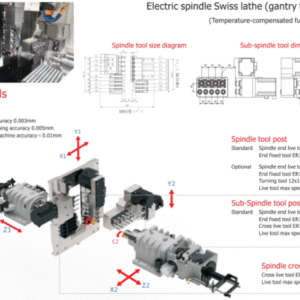

Electric Spindle with Large Bearings for Superior Cutting Performance

The machine features a robust electric spindle structure equipped with large bearings that provide excellent rigidity and vibration resistance. This allows the lathe to perform strong cuts with outstanding surface finish quality. With a maximum spindle speed of 6000 rpm and 11 kW high-power motor on both the main and sub-spindles, the TD365 ensures high torque output across the speed range, supporting heavy-duty machining while maintaining precision.

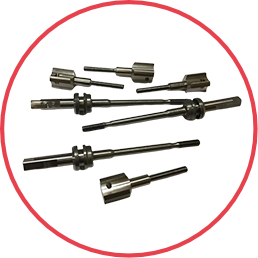

Long Axis Machining Capacity

The TD365 is capable of machining long shafts up to 220 mm in a single setup. This is especially beneficial for producing complex slender components while maintaining dimensional stability. The movable guide sleeve spline-type structure provides a smooth and accurate sliding motion, ensuring long-part machining without deflection or vibration.

Optimized Tool Layout for Chip-Free Rough Turning

The upper straight-line cutter structure significantly reduces chip buildup during rough turning operations. Combined with the temperature compensation function, the machine maintains accurate thermal stability even during long production cycles, ensuring consistent dimensional accuracy and reduced scrap rates.

Reinforced Screw Rod and Guide Rail System for Maximum Rigidity

The TD365 uses oversized screw rods and guide rails to deliver strong cutting rigidity:

-

32 mm + 25 mm double-nut ball screw system

-

30 mm + 25 mm wide linear guide rails

-

High-precision screw rod bearing seat structure

Each axis is equipped with high-power servo motors (1300W & 850W) to support high feed forces and maintain accuracy under full-load cutting. Linear movement speed reaches 30 m/min, enabling high-speed machining, shorter cycle times, and higher productivity.

Powerful Live Tooling System

The machine is equipped with a robust driven tool system using ER20 and ER16 collets, providing strong milling rigidity and excellent rotational accuracy. The live tool spindle achieves a maximum speed of 5500 rpm, enabling efficient milling, drilling, slotting, and tapping.

To support diverse machining needs, the TD365 includes S3, S4, and S5 driven tools, offering multi-directional cutting capability for complex part geometries. Optional configurations include:

-

Plug-in driven tool unit

-

Cyclone (whirling) milling head for threaded or long-profile machining

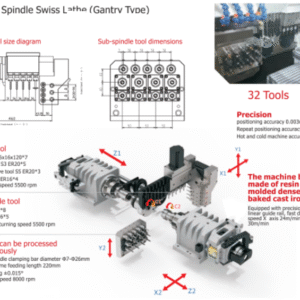

Comprehensive 25-Tool Configuration

The TD365 is equipped with a total of 25 tools, allowing highly flexible process planning:

-

Turning tools: 7 pcs, 16×16 mm

-

Side live tools: 5 pcs ER20

-

Spindle end: 4 ER16 fixed tools + 3 ER20 live tools

-

Sub-spindle end: 3 ER16 fixed tools + 3 ER16 live tools

This extensive tooling capability enables full-process machining, multiple operations in one setup, and reduced production time.

Compact and Beautifully Integrated Mechanical Structure

The machine bed, motor frame, bearing seat, and sub-spindle carriage are all designed as an integrated structure, ensuring a compact footprint and improved mechanical rigidity. Its streamlined exterior design not only enhances structural strength but also provides an aesthetic, modern appearance suitable for advanced machining facilities.

Technical Specifications

-

Control System: FANUC / SYNTEC

-

Travel Speed: X-axis 24 m/min, others 30 m/min

-

Main/Sub-Spindle Bar Capacity:

Without guide sleeve: φ7–φ35 mm

With guide sleeve: φ32 mm -

Max Drilling Diameter: φ12 mm (main), φ10 mm (sub-spindle)

-

Max Tapping Capacity: M10 (cross live tool), M8 (sub-spindle)

-

Driven Tool Speed: 5500 rpm

-

Machine Dimensions: 2700 × 1450 × 1800 mm

-

Machine Weight: 3600 kg

Conclusion

The TD365 Swiss-Type CNC Lathe is a high-performance turning center engineered for precision, versatility, and durability. Its powerful spindle system, reinforced structural design, and comprehensive tooling capacity make it ideal for manufacturers seeking high productivity and superior machining accuracy. Whether handling small precision components or longer complex shafts, the TD365 provides the stability, speed, and efficiency required for modern high-end production.

Reviews

There are no reviews yet.