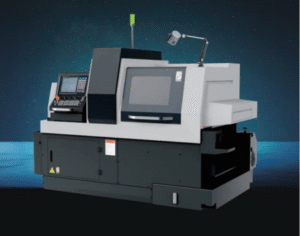

td366-swiss-type-cnc-lathe-32-tool-hydraulic-clamp-11kw

TD366 Swiss-Type CNC Lathe – High-Rigidity, High-Efficiency Precision Turning Solution

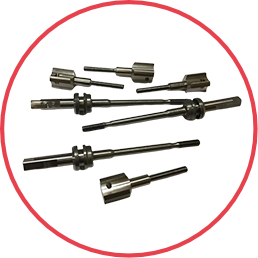

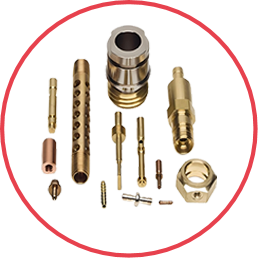

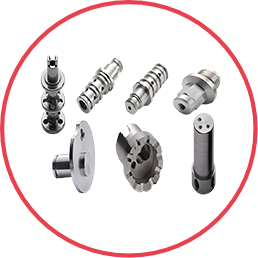

The TD366 Swiss-Type CNC Lathe is a high-performance, fully automated precision machining solution engineered for manufacturers who demand accuracy, rigidity, and superior reliability. Designed specifically for high-speed processing of small and medium-diameter long-axis components, the TD366 integrates a powerful mechanical structure, advanced spindle architecture, and a comprehensive tooling layout to support continuous production in automotive parts, aerospace components, medical devices, electronics, connectors, and general precision engineering.

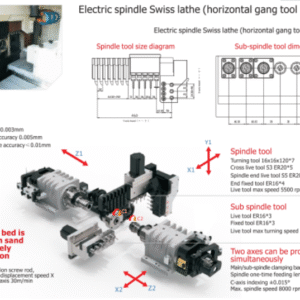

One of the key advantages of the TD366 is its main and sub-spindle hydraulic clamping system, which uses a hydraulic rotary cylinder to maintain strong, stable clamping throughout the machining process. This prevents material pull-back—a common issue during heavy drilling or aggressive material removal—ensuring cutting stability and superior dimensional accuracy. Whether drilling deep holes or performing high-load rough machining, the hydraulic clamping structure guarantees dependable performance.

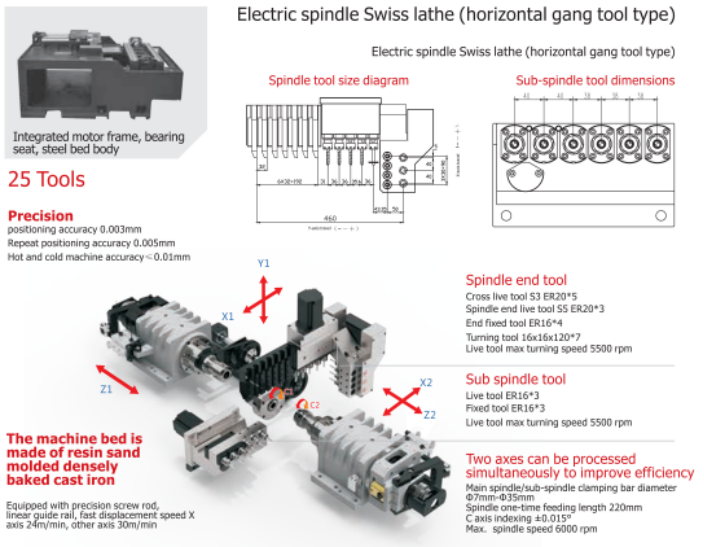

The TD366 utilizes a mechanical shaft spindle structure with a large-diameter bearing system, providing exceptional rigidity and high resistance to vibration. This structural advantage enables the machine to handle strong cutting forces while maintaining precision. With its temperature-compensation function, the TD366 ensures consistent accuracy even in long production runs where heat can influence machining tolerances.

To support high-load machining, the machine integrates a reinforced transmission system, including oversized ball screws with a dual-nut structure of 32 mm and 25 mm, as well as large guide rails measuring 30 mm and 25 mm. These design features significantly increase the machine’s stiffness and durability, ensuring stable performance when cutting challenging materials. The screw-rod bearing seats are engineered with a high-precision structural design, reducing backlash and improving long-term accuracy.

Each axis is powered by high-torque servo motors rated at 1300W and 850W, providing fast response and strong thrust for heavy-duty cutting operations. These motors allow the TD366 to maintain optimal cutting volume across demanding applications. With a maximum machine running speed of 30 m/min, the lathe delivers excellent efficiency while minimizing cycle times.

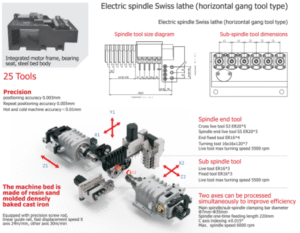

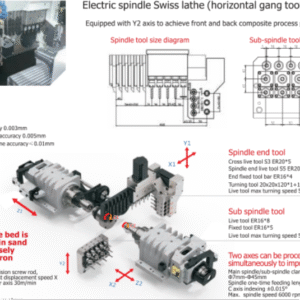

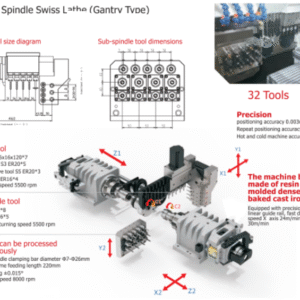

For milling and drilling work, the TD366 is equipped with ER20 and ER16 driven tools, offering strong milling rigidity and stable performance. Driven tools are available in S3, S4, and S5 configurations, enabling flexible machining in multiple directions. The machine supports a total of 32 tools, an exceptionally large tool capacity for its class, allowing manufacturers to complete complex multi-process machining tasks in one setup. Optional tool modules include a plug-in driven tool and a cyclone milling head, expanding the machine’s versatility for advanced component geometries.

The tool arrangement includes 7 turning tools (16×16 mm), 5 ER20 side live tools, multiple ER16 tools for main-spindle and sub-spindle machining, and a live tool maximum speed of 5500 r/min, enabling high-speed milling operations with excellent surface finish. This comprehensive tooling structure allows the TD366 to perform turning, milling, drilling, tapping, and complex contour machining all on one platform.

The machine’s mechanical components—including the bed, motor frame, bearing seats, and sub-spindle carriage—are designed as an integrated structure, resulting in enhanced rigidity, reduced vibration, and a clean, compact appearance. This structural integration ensures smooth operation even during heavy cutting, while also improving long-term machine durability.

With a 220 mm movable guide sleeve travel and a 360 mm maximum stroke without guide sleeve, the TD366 excels at processing long shafts and precision rod components. It can handle bar diameters of φ7–φ35 mm without a guide sleeve, and φ28 mm with a guide sleeve, providing flexibility for different types of machining requirements.

The TD366 is equipped with a high-pressure coolant system as standard, with optional pressure levels between 40–70 kg. High-pressure coolant improves deep-hole drilling efficiency, chip evacuation, and tool life—critical considerations for manufacturers producing long-axis and high-precision components.

With machine dimensions of 2700 × 1450 × 1800 mm and a weight of 3800 kg, the TD366 offers a stable and robust platform capable of supporting high-efficiency industrial production. Combined with its ultra-rigid structure, strong spindle performance, and large tool capacity, the TD366 delivers excellent productivity and machining precision, making it a reliable choice for modern manufacturing operations requiring speed, accuracy, and flexibility.

Reviews

There are no reviews yet.