td466-swiss-type-cnc-lathe-high-rigidity-precision-turning-milling

TD466 Swiss-Type CNC Lathe – High-Rigidity, High-Precision, High-Efficiency Production

The TD466 Swiss-Type CNC Lathe is engineered for demanding production environments where precision, rigidity, and long-term reliability are essential. With its upgraded mechanical structure, powerful spindle configuration, and high-speed linear motion system, the TD466 delivers excellent performance in complex turning and milling applications. Whether producing small precision components or executing heavy-duty cutting tasks, this machine provides stable performance and continuous accuracy.

Advanced Hydraulic Clamping System for Superior Stability

At the core of the machine is a main and sub-spindle hydraulic clamping structure built around a precision hydraulic rotary cylinder. This design ensures secure clamping during drilling and heavy cutting, effectively preventing material pull-back caused by poor clamping force. The result is more stable machining, reduced scrap rate, and consistent product accuracy—even under large cutting loads.

Optimized Mechanical Shaft Structure & Strong Cutting Capability

The TD466 adopts a mechanical shaft architecture with oversized bearings, providing exceptional rigidity and vibration resistance. This heavy-duty base structure allows the machine to maintain excellent stability during high-speed, high-thrust machining operations. As a result, the TD466 supports large material removal rates while maintaining dimensional accuracy and surface quality.

The machine is capable of processing a long axis length of up to 220 mm in a single operation, making it ideal for the production of long, slender, or multi-process components.

Temperature Compensation for Continuous Precision

To maintain accuracy in long machining cycles, the TD466 integrates a temperature-compensated function. This feature automatically adjusts thermal displacement, ensuring long-term dimensional stability during continuous operation.

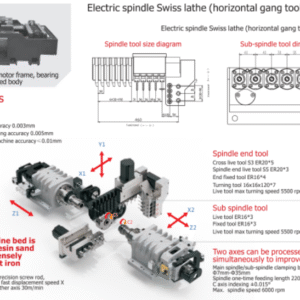

High-Rigidity Linear Tooling System

The upper straight-line cutter layout is designed to minimize tool deformation and eliminate slag during rough turning. This improves cutting efficiency, reduces secondary cleaning, and provides a smoother workflow in high-volume production lines.

Large Precision Screw Rods & Guide Rails

To further enhance rigidity, the TD466 is equipped with:

-

Ø32 mm and Ø25 mm double-nut ball screws

-

30 mm and 25 mm heavy-duty guide rails

-

High-precision screw rod bearing seats

These components significantly improve transmission stiffness, reduce backlash, and support high-thrust machining.

Each axis is powered by high-power servo motors (1300W and 850W), ensuring rapid positioning, smooth acceleration, and reliable performance under heavy cutting conditions.

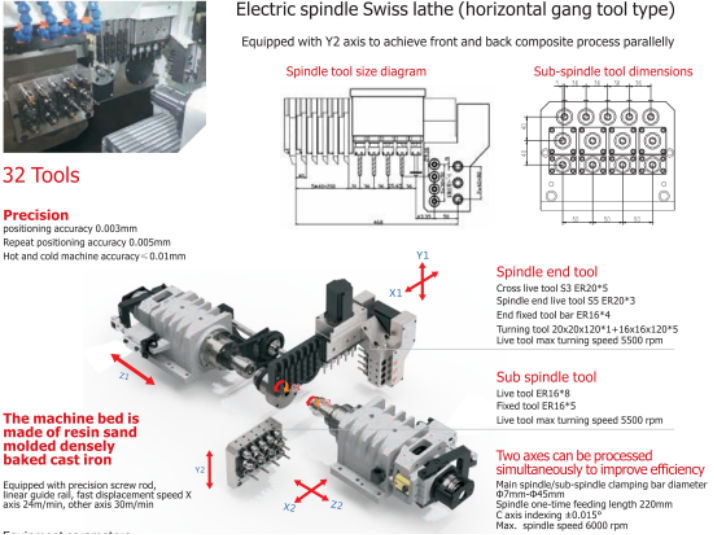

High-Speed Live Tooling for Powerful Milling Capability

The TD466 delivers excellent milling performance through its:

-

ER20 and ER16 driven tool system

-

High rigidity tooling design

-

Maximum live tool speed of 5,500 r/min

Driven tool sets S3, S4, and S5 are available to support multi-directional machining, allowing operators to complete complex turning-milling operations in one setup and significantly reduce cycle time.

Large Tool Capacity for Flexible Production

The machine supports up to 32 tools, giving operators a wide selection of turning, milling, drilling, and tapping tools for versatile production tasks. It can also be equipped with:

-

Plug-in driven tools

-

Cyclone milling heads

These upgrades enable additional machining strategies such as polygon turning or high-speed milling, making the TD466 suitable for the production of precision automotive, electronics, and medical components.

High-Speed Structure for Maximum Output

With a running speed of up to 30 m/min, the TD466 ensures fast cycle times and higher productivity. Combined with high-speed machining capabilities, the machine helps reduce manufacturing costs while maintaining premium accuracy and finish quality.

Compact, Integrated Mechanical Design

The machine bed, motor frame, bearing seats, and sub-spindle carriage are all structurally connected, forming a compact and visually clean machine body. This integrated design improves rigidity, enhances stability, and simplifies maintenance. The TD466 also comes standard with high-pressure coolant, with optional 40–70 kg systems, supporting efficient chip removal and extended tool life.

Technical Highlights – TD466

Control System Options

-

FANUC

-

SYNTEC

Processing Range

-

X-axis travel speed: 24 m/min

-

Other axes travel speed: 30 m/min

-

Max bar diameter without guide bushing: φ7–45 mm

-

With guide sleeve: φ32 mm

-

Spindle end max drilling diameter: φ12 mm

-

Spindle end max tapping diameter: M10

-

Sub-spindle max drilling: φ10 mm

-

Sub-spindle max tapping: M10

-

Cross live tool max drilling: φ12 mm

-

Cross live tool max tapping: M10

Spindle Performance

-

Main spindle motor: 11 kW

-

Sub-spindle motor: 11 kW

-

Max spindle speed: 6000 r/min

-

Guide sleeve travel: 220 mm

-

Without guide sleeve: 360 mm

Tool Configuration

-

Turning tools: 1 pc 20×20 mm + 5 pcs 16×16 mm

-

Side live tools: 5 × ER20 live tools

-

Spindle-end tools: 4 ER16 fixed + 3 ER20 live tools

-

Sub-spindle tools: 5 ER16 fixed + 8 ER16 live tools

Machine Size & Weight

-

Dimensions: 2700 × 1450 × 1800 mm

-

Machine weight: 4000 kg

Reviews

There are no reviews yet.