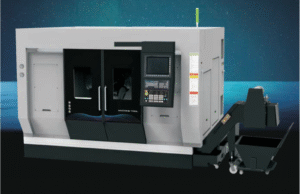

we800-dual-spindle-dual-turret-turn-mill-lathe

WE800 Dual-Spindle Dual-Turret Turn-Mill Lathe – 800-Word Description

The WE800 dual-spindle dual-turret turn-mill lathe is an advanced, high-precision multi-tasking machine designed to execute complex machining operations, including turning, milling, drilling, tapping, and contouring, in a single setup. Engineered for efficiency, rigidity, and precision, it is ideal for processing high-accuracy parts in automotive, aerospace, energy, and precision hardware industries. Its dual-spindle and dual-turret architecture allows simultaneous operations, greatly enhancing productivity and reducing cycle times for complex components.

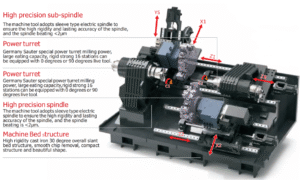

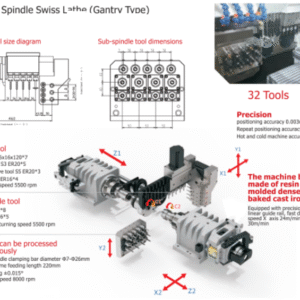

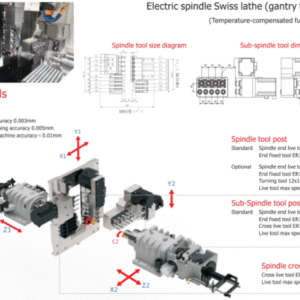

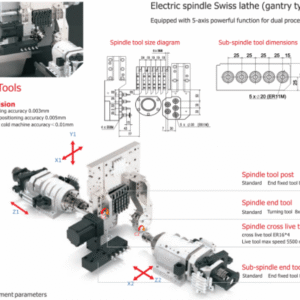

Dual-Spindle Dual-Turret Design for Maximum Efficiency

The WE800 features a German Sauter 16-station BMT55 servo power turret for both main and sub-spindles. This allows for fast tool changes with a tool change repeat positioning accuracy of 0.003mm, ensuring consistent performance during high-speed operations. All 16 stations are compatible with 0° or 90° live tooling, offering the flexibility to perform milling, drilling, tapping, or other auxiliary operations without additional setup. This dual-turret configuration, coupled with dual-channel machining, enables the main and sub-spindles to operate independently, effectively cutting overall production time.

High-Performance Main and Sub-Spindles

The main spindle utilizes an A2-6 built-in electric spindle with 18.5KW (SYNTEC) or 22KW (FANUC) power, offering high rigidity, stable rotation, and fast response speed. The sub-spindle is equipped with an A2-5 electric spindle with 11KW, designed to reduce vibration and thermal deformation at high speeds. Both spindles maintain a runout of <2μm, ensuring high surface finish quality and precision suitable for both large-diameter and high-precision applications. This configuration allows simultaneous dual-spindle machining, optimizing throughput for complex parts.

XY/Z-Axis Precision and Rigidity

The WE800’s X, Y, and Z axes are powered by 1.8KW high-precision servo motors. Each axis uses high-precision double ball screws and large 40/32mm lead screw range with 12/10mm pitch, along with 45/35 roller guide rails to guarantee high positional accuracy and repeatability. The interpolation Y-axis design keeps the turret’s center of gravity within the saddle slide rail range, significantly enhancing milling rigidity. With a ±50mm Y-axis stroke, even complex geometries can be machined in compact spaces, enabling large-diameter part processing without compromise.

Machine Structure and Bed Design

The WE800 is constructed on a high-rigidity cast iron 30° overall slant bed, which provides excellent vibration damping, structural stability, and chip evacuation. The machine’s body, motor frame, bearing seat, and X-axis carriage are fully integrated to enhance mechanical accuracy and rigidity. This structure ensures stable, reliable machining even under heavy cutting loads and long-cycle operations, while maintaining a compact footprint suitable for medium- to large-sized factories.

Super Cutting Capability

Equipped with high-speed, high-precision hydraulic rotary cylinders, precision collets, and high-rigidity power chucks, the WE800 delivers superior cutting performance. It can handle tough and high-strength materials efficiently, maintaining consistent surface quality and dimensional accuracy. Its milling cutter supports speeds up to 6000 r/min, with tool shank diameters from φ1mm to φ20mm, ensuring flexibility across a variety of machining tasks.

Traveling Range and Axis Speeds

The WE800 offers extensive travel ranges to accommodate various part sizes:

-

X1/X2 Axis: 320mm

-

Z1/Z2 Axis: 800mm

-

Y1/Y2 Axis: ±50mm

-

ZB Axis: 800mm

The machine’s axis traveling speeds ensure high efficiency:

-

XY Axis Max. Traveling: 24m/min

-

Z Axis Max. Traveling: 16m/min

-

Y Axis Max. Traveling: 30m/min

These speeds, combined with precise servo control, allow rapid and accurate tool movement for both roughing and finishing operations.

Technical Highlights

-

Positioning Accuracy: 0.005mm

-

Repeatability: X/Y/Z: 0.005 / 0.005 / 0.008mm

-

Turret Tool Count: 16 stations per turret

-

Outer Diameter Tool Holder: 25mm

-

Inner Diameter Tool Holder: φ32mm

-

Max Processing Bar Diameter: Main: φ52mm / Sub: φ45mm

-

Max Processing Length: 380mm

-

Max Processing Diameter: φ280mm

Compact Size and Ergonomics

Despite its dual-spindle and dual-turret configuration, the WE800 maintains a compact machine size of 2984 × 2825 × 2044mm and a manageable weight of 8T. Its slant-bed structure promotes smooth chip removal, ergonomic tool accessibility, and a clean, organized workspace.

Automation Compatibility

The machine can be integrated with robotic loading and unloading systems, enabling automated production lines. This reduces labor requirements, ensures consistent quality, and supports continuous operation for high-volume manufacturing environments.

Conclusion

The WE800 dual-spindle dual-turret turn-mill lathe combines advanced turret technology, high-precision spindles, rigid construction, and full Y-axis interpolation to deliver a high-efficiency, multifunctional machining platform. It excels at handling complex workpieces, large-diameter components, and multi-step processes in a single setup, making it a top choice for industries requiring precision, speed, and versatility in turning–milling operations.

Its combination of dual spindles, dual 16-station turrets, high-speed axes, and compact design ensures that manufacturers can reduce cycle times, maintain consistent quality, and achieve superior surface finishes, all within a single, automated machining solution.

Reviews

There are no reviews yet.