wu800-dual-spindle-dual-turret-cnc-turn-mill-center

WU800 Dual-Spindle Dual-Turret Turn-Mill CNC Machine – 800-Word Product Description

The WU800 is a high-performance dual-spindle, dual-turret turn-mill machining center designed to complete complex turning, milling, drilling, tapping, and machining cycles in a single setup. With its powerful configuration, advanced mechanical structure, and precision-engineered components, the WU800 delivers exceptional productivity and accuracy for demanding industries such as automotive, aerospace, medical, hardware, and precision manufacturing.

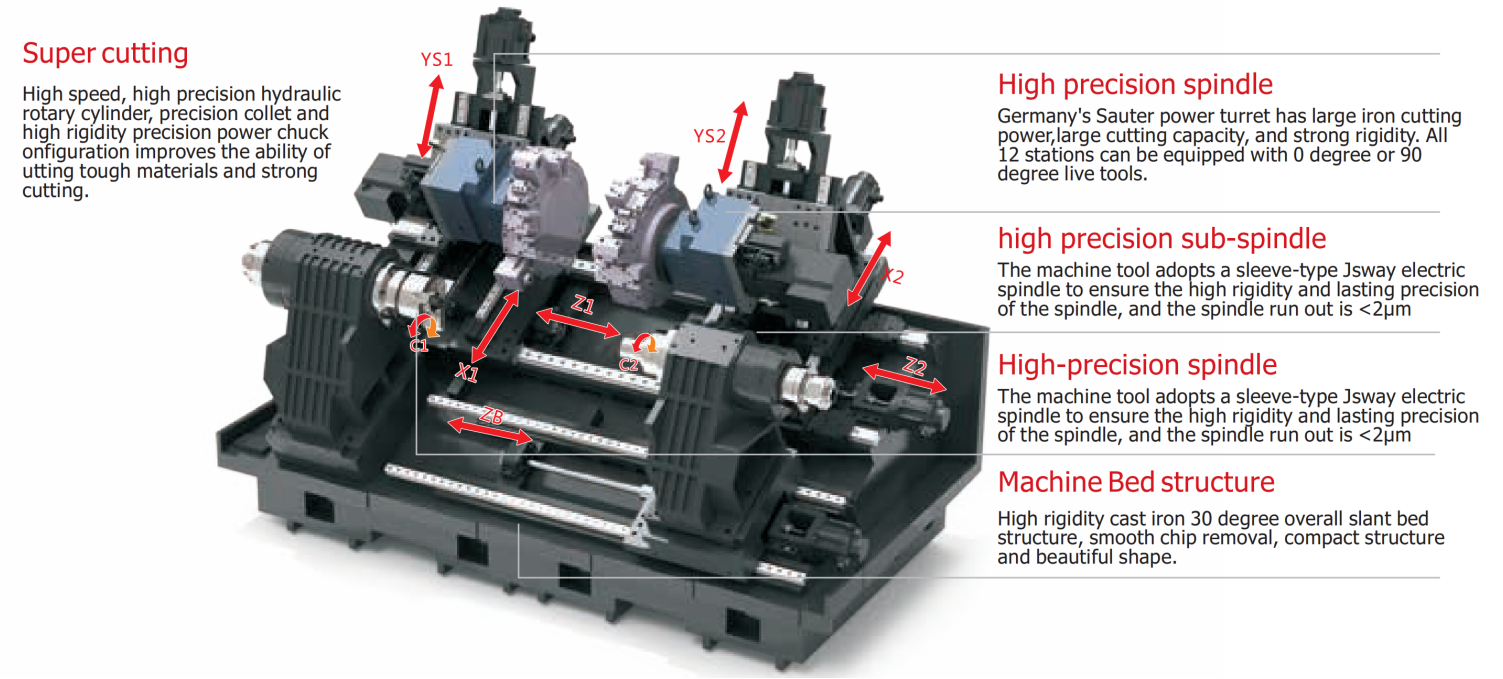

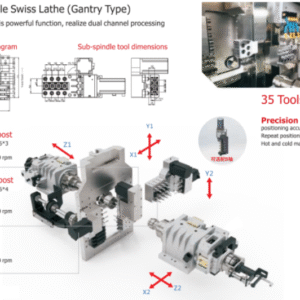

At the core of the WU800 is its dual-spindle, dual-turret architecture, which allows fully independent or synchronized machining. Each turret can work simultaneously with either the main spindle or sub-spindle, enabling true dual-channel processing. This dramatically shortens total cycle time, reduces workpiece loading operations, and supports complete machining of complex parts in one clamping. The machine integrates a German Sauter 16-station BMT55 servo power turret for fast tool indexing. With a tool-change repeatability of 0.003mm, the turret offers outstanding stability during high-load milling. All 16 stations support both 0° and 90° live tools, providing unmatched flexibility for multi-axis milling, drilling, and contouring operations. Its high iron-cutting power and strong rigidity make it ideal for heavy-duty material removal.

The spindle system is engineered for high power, low vibration, and outstanding accuracy. The main spindle is available with either an 18.5 kW SYNTEC or 22 kW FANUC built-in electric spindle, paired with an A2-6 spindle nose capable of supporting challenging turning and milling tasks. The sub-spindle, using an 11 kW built-in electric spindle and an A2-5 nose, enables smooth part hand-off, balanced cutting, and secondary operations. Both spindles feature a sleeve-type Jsway electric spindle structure, ensuring exceptional thermal stability and long-term accuracy. With < 2 μm spindle runout, the WU800 is suitable for applications requiring high precision, strict tolerances, and premium surface finishes.

The machine features 1.8 kW servo motors on the X, Y, and Z axes, ensuring fast response and consistent positioning during high-speed machining. Every axis is equipped with high-precision double nuts ball screws, with large-lead specifications of 40/32mm screws and 12/10mm pitch. This configuration minimizes backlash, improves thrust and rigidity, and ensures stable positioning accuracy under high-load machining. The linear guideway system uses 45/35mm roller guide rails, delivering high rigidity, shock resistance, and excellent dynamic performance.

One of the WU800’s key advantages is its reinforced machine structure. The machine tool body, motor base, bearing seat, and X-axis drag plate are built using a high-strength connected structure. This integrated design increases rigidity across the entire mechanical system, maintaining precision during prolonged machining cycles and heavy cutting operations. The 30° slant bed cast-iron base provides a stable foundation with excellent vibration absorption and smooth chip evacuation, while maintaining a compact footprint.

The WU800 adopts a specially optimized mechanical Y-axis design, ensuring that the turret’s center of gravity always remains within the saddle area. This significantly increases milling rigidity, improves accuracy during off-center machining, and enables stable performance even in demanding milling applications. With a long Y-axis travel of ±50mm, the turret can easily reach complex features and support interpolation milling operations. This allows the machine to perform high-precision milling, engraving, cross-drilling, angular machining, and contouring—all within a compact spatial layout.

Equipped with dual turrets and dual spindles, the WU800 becomes a true multi-tasking intelligent turning-milling center. It can simultaneously perform carving, milling, tapping, drilling, and secondary operations, dramatically increasing productivity. The high-precision hydraulic rotary cylinder, precision collet chuck, and rigid power chuck ensure exceptional clamping force, enabling super-cutting capability even on difficult materials such as stainless steel, alloy steel, hardened steel, and high-strength metals.

The Sauter power turret further enhances machining capability, offering large cutting capacity and extreme rigidity. All 16 tool stations accept either axial or radial live tools, making them suitable for machining deep holes, side holes, and angled features without requiring secondary fixtures or additional equipment. Combined with <2 μm spindle runout, the WU800 ensures precise, repeatable machining for long production runs.

The machine is also designed with ease of use and maintenance in mind. Its compact layout, slanted bed design, and enclosed working space promote smooth chip flow and easy cleaning. The rigidity, precision, and structural stability of the WU800 deliver long-term reliability and outstanding performance in medium-to-mass production environments.

Overall, the WU800 dual-spindle dual-turret turn-mill machining center is engineered for manufacturers seeking high efficiency, reduced cycle time, and uncompromising accuracy. Its advanced mechanical structure, powerful spindle system, high-precision turrets, and flexible tooling options make it a comprehensive solution for producing complex, multi-process components in a single clamping—significantly improving throughput, precision, and profitability.

Reviews

There are no reviews yet.