wy300-dual-spindle-dual-turret-cnc-turn-mill-center

WY300 Dual-Spindle Y-Axis CNC Turn-Mill Center — 800-Word Description

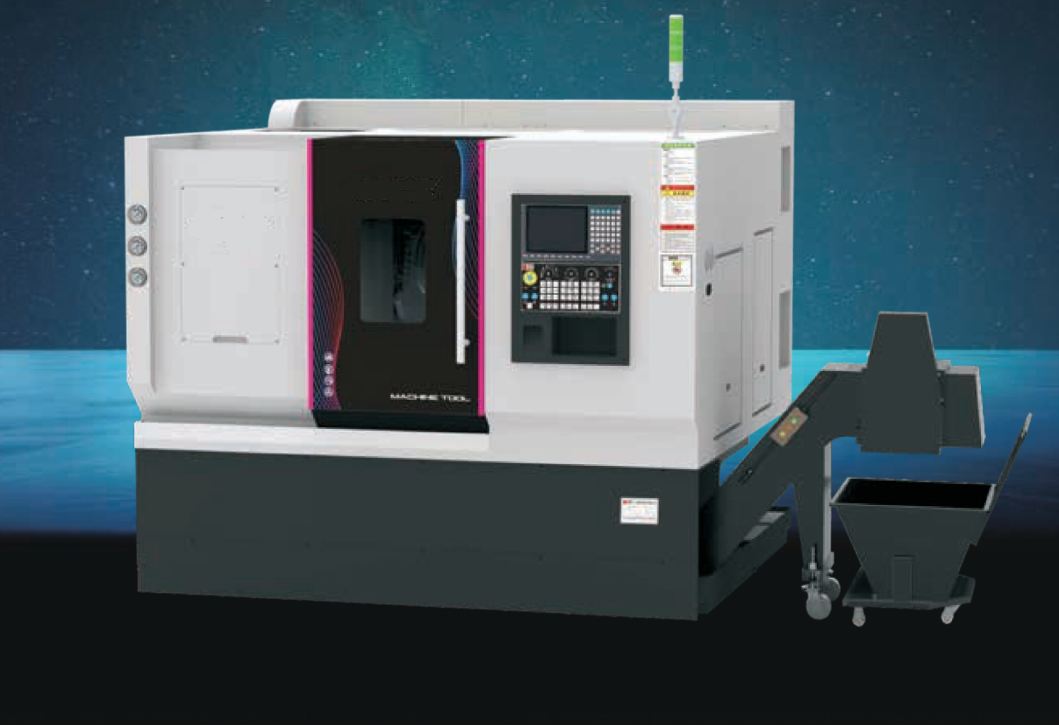

The WY300 dual-spindle, dual-channel Y-axis CNC turning and milling center is engineered for high-precision, high-efficiency machining of complex components in a single setup. Designed to serve industries that require accuracy, productivity, and stable long-term machining performance, the WY300 combines rigid machine mechanics, dual spindles, synchronized interpolation control, and a powerful Y-axis power turret to deliver outstanding versatility for both mass production and precision prototyping.

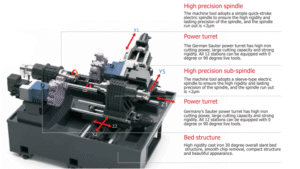

High-Precision Dual-Spindle Layout

The WY300 features a main spindle and sub-spindle, both equipped with an A2-5 spindle nose to provide consistent clamping performance and stable support for bar materials and complex workpieces. Both spindles offer a maximum bar capacity of φ45mm and a through-hole diameter of φ56mm, allowing efficient machining of medium-diameter cylindrical parts. Whether the operator is performing turning, milling, drilling, or synchronized transfer machining, the dual-spindle configuration enables seamless part handover, significantly shortening part cycle times.

The dual-spindle system is designed for high-performance continuous machining. Each spindle is powered by an 11KW built-in motor, providing rapid acceleration, reduced vibration, and outstanding stability during high-speed cutting. The built-in spindle design minimizes heat deformation, ensuring superior dimensional accuracy and maintaining spindle runout within strict tolerances for improved surface finish quality.

Advanced Turning and Milling with Y-Axis Capability

Equipped with a Y-axis stroke of ±50mm, the WY300 supports complete turning and milling functions in one machine. This capability enables operators to process off-center features, drill side holes, engrave complex profiles, and mill precise slots or flats without requiring secondary fixtures or multiple machines. The addition of the Y-axis dramatically expands machining flexibility, reduces setup time, and increases overall productivity.

The interpolation Y-axis system ensures that the turret’s center of gravity stays within the saddle slideway range, greatly enhancing rigidity during milling operations. This mechanical design minimizes vibration and prevents deflection even during aggressive cuts, making the WY300 suitable for machining tough materials such as alloy steel, stainless steel, and structural metals used in automotive parts, instrument components, and aerospace fittings.

Precision Power Turret for Complex Tooling Needs

The WY300 is equipped with a high-performance servo-driven power turret, customizable with BMT tooling interfaces. The turret’s strong servo motor drive (3.1KW or 2.7KW depending on the configuration) allows fast, accurate tool indexing and stable power transmission for heavy-duty milling. With its precision tool-change servo motor (750W), the turret ensures repeat positioning accuracy during continuous machining, enabling long-term reliability even in demanding manufacturing environments.

The power turret supports all essential machining operations—turning, milling, drilling, tapping—within a single setup. With up to 12 stations or more depending on configuration, operators can load a wide range of tools for multi-process machining without needing manual intervention, significantly reducing production downtime.

Optimized Machine Travel and Rapid Feed Performance

The WY300 provides generous travel ranges suitable for a wide variety of parts:

-

X1 Axis Travel: 180mm

-

X2 Axis Travel: 320mm

-

Z1 Axis Travel: 340mm

-

Z2 Axis Travel: 320mm

-

Y-Axis Travel: ±50mm

These axes are driven by high-precision servo motors—2.4KW or 1.8KW depending on the system configuration—to ensure high tool stability and exceptional dynamic response. The maximum displacement speed reaches 30m/min, enabling rapid positioning and reduced idle time between machining operations. This ensures fast cycle times while maintaining outstanding machining accuracy.

Superior Machining Accuracy and Repeatability

The WY300’s mechanical structure is built around a rigid cast-iron base, optimized through FEA simulations to enhance vibration absorption and long-term accuracy retention. High-precision linear guideways and double-nut ball screws ensure positioning accuracy of 0.005mm and repeatability of 0.005mm across all major axes.

This level of mechanical precision ensures high-quality surface finishes and dimensional consistency, even during extended periods of mass production. The WY300 is ideal for industries requiring strict tolerances—such as electronics, precision machinery, automotive components, hydraulic parts, and medical equipment.

Powerful and Energy-Efficient Motor System

The machine’s motor system is designed for high efficiency and reliability:

-

Z1 / Z2 / X2 axis servo motors: 2.4KW / 1.8KW

-

X1 axis servo motor: 1.8KW with brake

-

Y-axis servo motor: 2.4KW / 1.8KW

-

Main spindle: 11KW

-

Sub-spindle: 11KW

-

Power turret motor: 3.1KW / 2.7KW

-

Turret tool-change motor: 750W

This ensures excellent torque output for heavy cutting and stable continuous machining, even with difficult-to-cut materials.

Compact, Rigid, and Well-Structured Machine Body

The WY300 integrates a space-efficient footprint of 2500 × 2450 × 2050 mm while supporting a machine weight of 5.3T. The heavy-duty cast-iron structure reinforces machine rigidity, minimizes thermal drift, and enhances long-term stability for precision results.

Reviews

There are no reviews yet.